sawdust maker

Established Member

I lost!

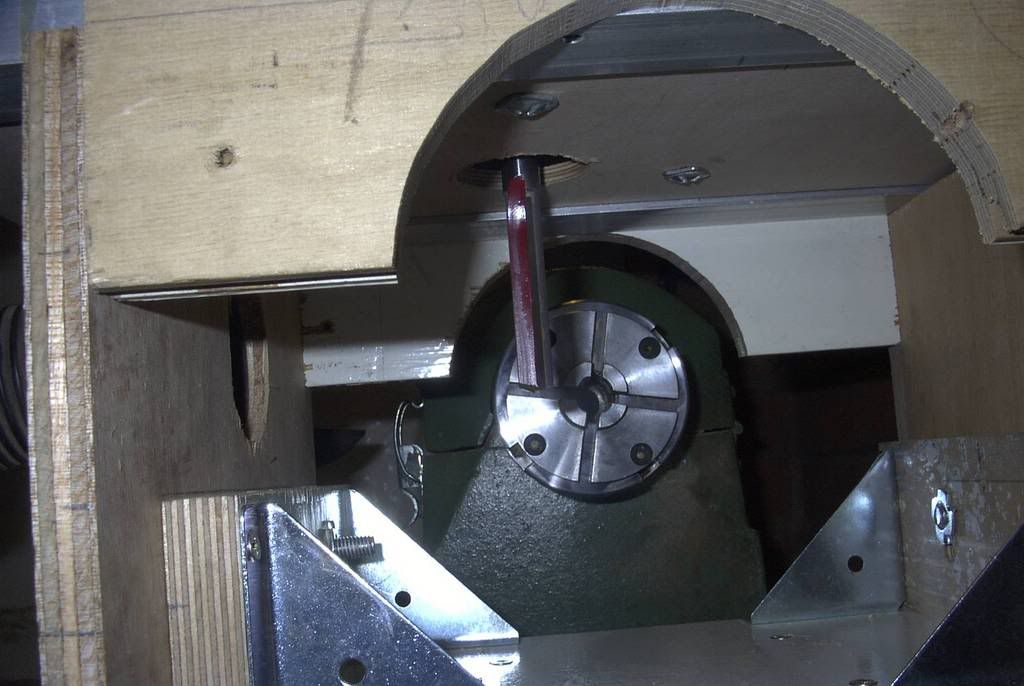

About a week ago I asked if using a router on a lathe in a jig could you make a 4" dia. dowel. The answers I got were inconclusive, so I thought I would have a go and made this.

The base ran on nine roller bearings and I was well chuffed when it had no discernable vertical or horizontal movement.

The router was fix on a sliding base plate adjuster with the large black knob.

.

.

I set it up to turn a 3.5" softwood cylinder. The result was very disappointing.

.

.

But at least I know the answer to my question. It doesn't work.

On the brighter side most of the bits were from my scrap box.

About a week ago I asked if using a router on a lathe in a jig could you make a 4" dia. dowel. The answers I got were inconclusive, so I thought I would have a go and made this.

The base ran on nine roller bearings and I was well chuffed when it had no discernable vertical or horizontal movement.

The router was fix on a sliding base plate adjuster with the large black knob.

I set it up to turn a 3.5" softwood cylinder. The result was very disappointing.

But at least I know the answer to my question. It doesn't work.

On the brighter side most of the bits were from my scrap box.