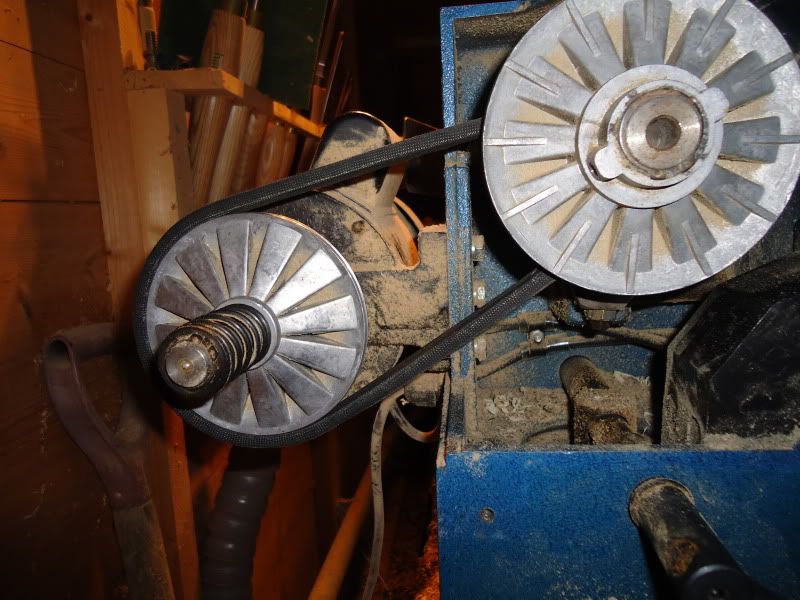

Hi all. I'm pretty new to wood turning. I have an SIP variable speed lathe, which I bought second hand. I have been enjoying myself making pens, small bowls etc. I had the joy of watching my lathe smash itself to bits on Sunday. The drive belt started to fray, caught on the pulleys and they flew to bits. I need all four pully halves. I went on the SIP website and they want nearly 40 quid each half! Plus a belt and postage Im looking at over 200 quid to fix it. To be honest, I can't afford that, not with family etc. Does any one have any ideas as to other makes whos insides are the same, but a bit cheaper. Or maybe a headstock wich is scrap but with useable pulleys? I'm gratefull for any ideas to get me going again.

Thanks

Gubby

Thanks

Gubby