jimi43

Established Member

Hello

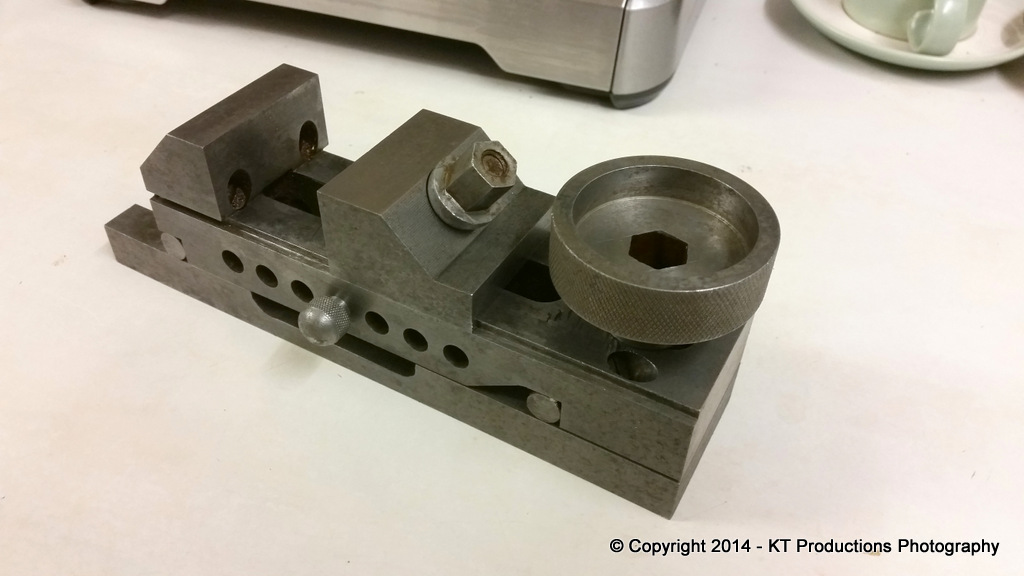

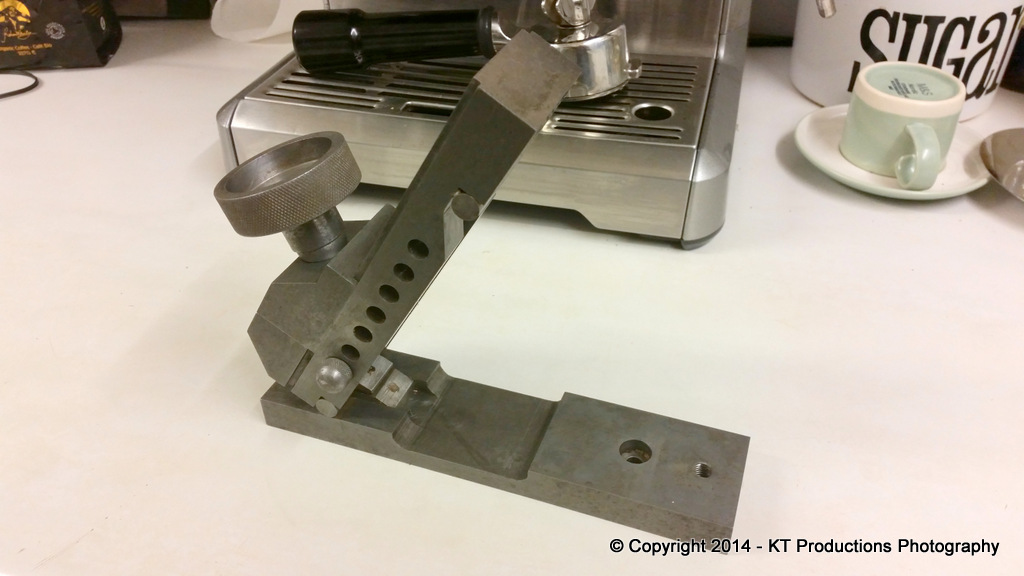

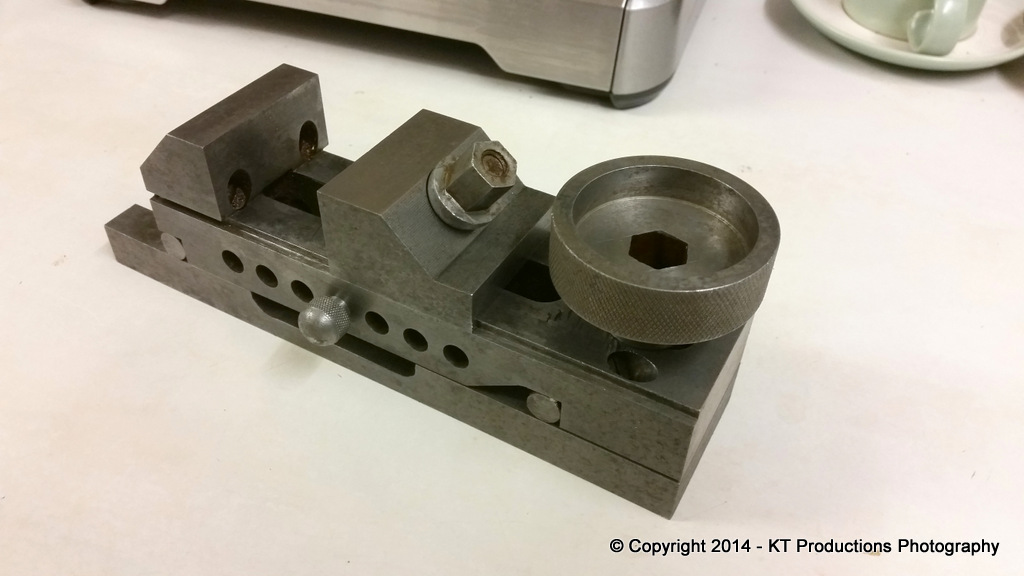

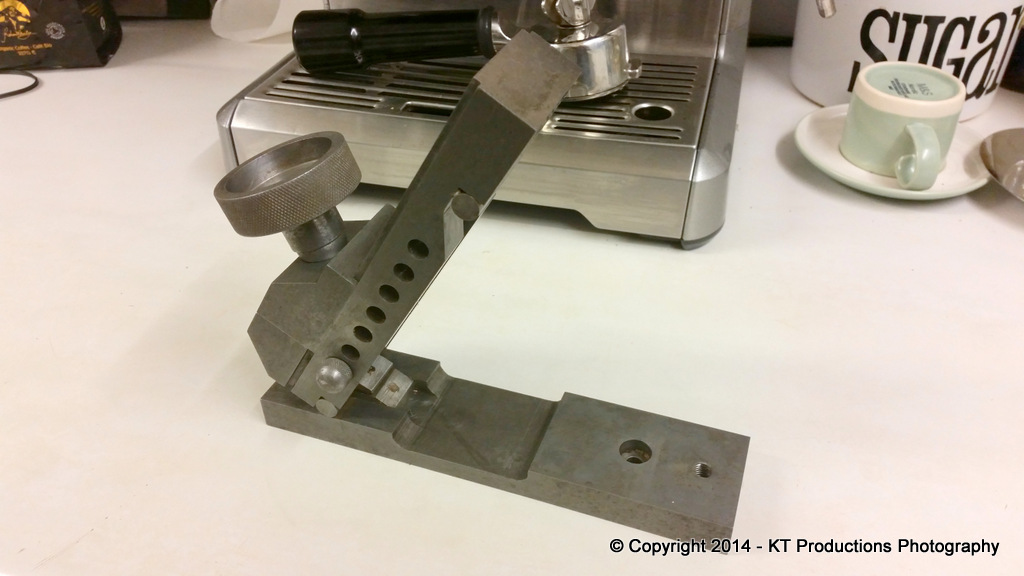

Some time ago...I bought a vise at a bootfair for a couple of quid. It looked quality so I snapped it up and cleaned it.

It wasn't until I got the mill and dragged it out this evening for a hold down job that I realised that it was a sine vise!!

While I was cleaning it, I noticed the screw holding down the top half...

That was a bit of a revelation!

So I investigated the vise using Google and being familiar with sine bars...I tried "sine vise" and realised what I had was a bit more special than a plain old machine vise!

Now the question.

I thought there was something missing because clearly you should be able to lock it at any angle you want....and all the examples I have seen online have either a bracket on the side of differing types...or a screw that works from the back to lock the top half up at different angles depending on how far the screw is wound in.

But this vise has neither...nor does it have any visible locations where a missing one would have been fitted.

So..the question is..how the hell do I lock this at whatever angle I want. Surely..gauge blocks are not left in place..that wouldn't work...so does anyone know?

Any help gratefully received.

Jimi

Some time ago...I bought a vise at a bootfair for a couple of quid. It looked quality so I snapped it up and cleaned it.

It wasn't until I got the mill and dragged it out this evening for a hold down job that I realised that it was a sine vise!!

While I was cleaning it, I noticed the screw holding down the top half...

That was a bit of a revelation!

So I investigated the vise using Google and being familiar with sine bars...I tried "sine vise" and realised what I had was a bit more special than a plain old machine vise!

Now the question.

I thought there was something missing because clearly you should be able to lock it at any angle you want....and all the examples I have seen online have either a bracket on the side of differing types...or a screw that works from the back to lock the top half up at different angles depending on how far the screw is wound in.

But this vise has neither...nor does it have any visible locations where a missing one would have been fitted.

So..the question is..how the hell do I lock this at whatever angle I want. Surely..gauge blocks are not left in place..that wouldn't work...so does anyone know?

Any help gratefully received.

Jimi