Shultzy

Established Member

The next item on my workshop build is a router table. The design has been cribbed from Joe Johns efforts and those I've seen on the forum. I've adapted it fit my needs, height wise and the dust extraction. The top rh drawer will be false with the nvr switch attached. The drawer front under the router access door is also false to provide a slope for dust extraction.

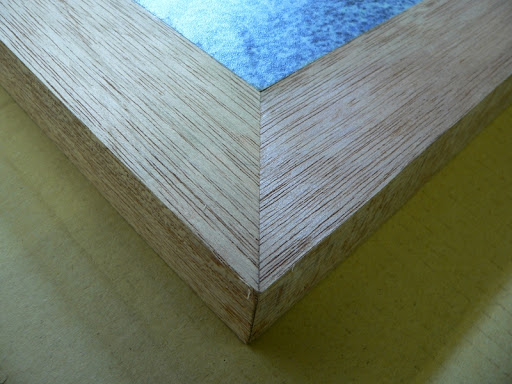

The basic shell is 18mm ply (which I had to buy ). The top is a piece of worktop I salvaged from Freecycle, it's just sitting on top to be out of the way.

). The top is a piece of worktop I salvaged from Freecycle, it's just sitting on top to be out of the way.

The face frame is meranti, I think, which was formally a threshold rescued from a double glazing skip. It's "pocket-holed" with the Kreg jig I had on offer from Axminster (thanks to the "head's-up" on the forum). A great piece of kit and easy to use.

The basic shell is 18mm ply (which I had to buy

The face frame is meranti, I think, which was formally a threshold rescued from a double glazing skip. It's "pocket-holed" with the Kreg jig I had on offer from Axminster (thanks to the "head's-up" on the forum). A great piece of kit and easy to use.