bobbydazzler

Member

.....does anyone know if a 2.6 metre 50mmx50mmx3mm steel box section will sag in the middle (under moderate pressure)?

I should explain....I'm gonna install a 3 metre wide (I know, too much stuff) by 800mm deep PC desk/bench made from two pieces of high density (?) 1.5Mx800mmx25mm chipboard (yuk). I'll have to join these in-situ, due to limited access, with glue plus 4 butterfly clamp bolts.

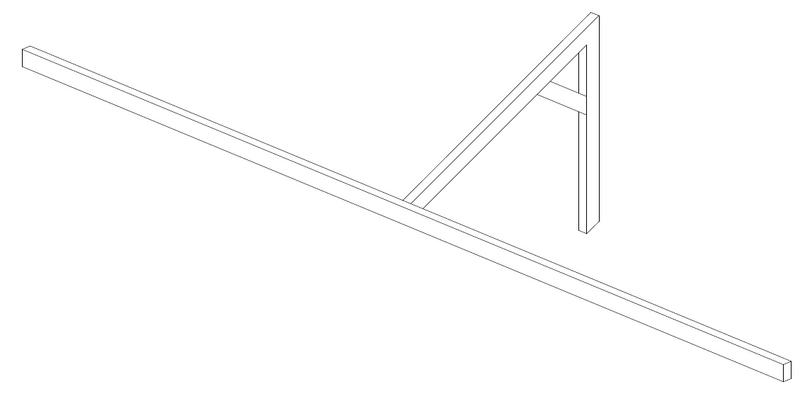

It'll be supported at the back with a wall batten. I hope to get away with insetting the two legs at the front (can't have more) by around 200mm....but this still gives me a span (or apron if you will) of 2.6 metres.....hence the question.

I can hide the steel box section behind a false wood apron.

While I'm at it I'll also make the two legs out of the same steel and weld all three pieces up (not in situ I hasten to add )

)

Any advice most gratefully received!

I should explain....I'm gonna install a 3 metre wide (I know, too much stuff) by 800mm deep PC desk/bench made from two pieces of high density (?) 1.5Mx800mmx25mm chipboard (yuk). I'll have to join these in-situ, due to limited access, with glue plus 4 butterfly clamp bolts.

It'll be supported at the back with a wall batten. I hope to get away with insetting the two legs at the front (can't have more) by around 200mm....but this still gives me a span (or apron if you will) of 2.6 metres.....hence the question.

I can hide the steel box section behind a false wood apron.

While I'm at it I'll also make the two legs out of the same steel and weld all three pieces up (not in situ I hasten to add

Any advice most gratefully received!