Mortise cutting jig, for use with a router.

• Pictures 1 and 2 show the jig, a piece of acrylic sheet or mdf or ply about 6mm thick. Drill holes for fixing to your router, fix to your router, then fit a small cutter and plunge through, this will give a centre line with which to work.

• Mark a line through centre and square to the router, drill and fit 2 dowels either plastic, as I have, or timber, at a distance near to the edge.

• Here false plate is fitted to router.

• Here Router is set onto piece to be mortised, then turn the router until the pegs are touching each side and plunge to cut.

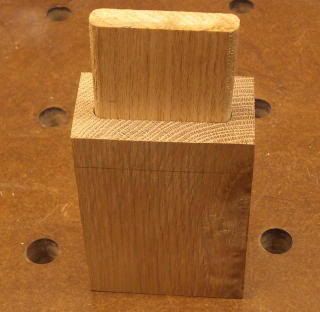

• Here in picture 5 I am using the additional fitment that allows the routing of mortises near to the end. A spacer of the same thickness as the piece to be mortised must be fitted to the end of the extending jig.

• Picture 6 shows the extending jig.

• Picture 7 shows all the components.

Your mortise will always be central with the use of a jig like this.

Derek.