:!: :arrow: :idea: :arrow:

Right then, yesterday I spent a few hours in the shop messing around with this plane, hoping for something of a result like the picture i found off the internet on the first post of this topic.

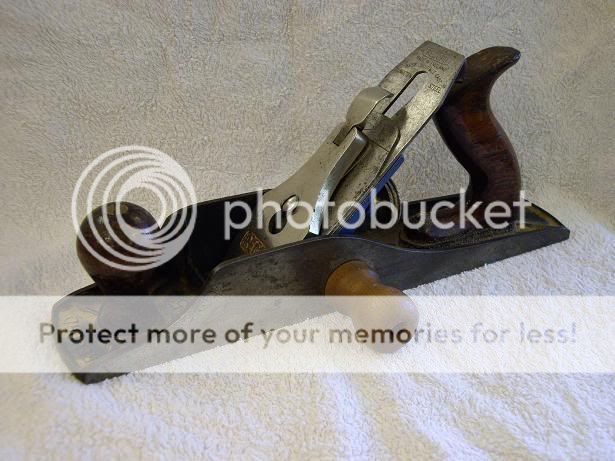

Here is the BEFORE pics, the surface of the plane is slightly already cleaned up, because it was an after-thought to take pics.

As I said the surface is slightly cleaned up, because I didnt think to take pictures until i started.

WORK IN PROGRESS*

As the picture below shows, I cramped up a thin long piece of plywood and nailed on some 60 grit sanding paper. I kept running the plane surafce up and down this until all the rust was lost. I done the two side edges this way as well. I also did this method with the other metal parts.

I then re-done the same method but I changed the paper to 80 grit. After doing all of this, I sprayed WD-40 on all cleaned up surfaces and rubbed it in with a cloth, this was to preserve the surafces.

I then had to actually sort the blade out now there was no rust on it. Cleaned up the back of the blade on a coarse 250 grit diamond stone first until it was flat and then finished it on a 600 grit. Obviously then just sharpened up the usual way.

FINISHED! *

The finished product...

Altogether now, as you can see I couldn't wait to see if it cut nicely before taking the pictures!!! Lovely cut I must say :lol: Its all in the sharpening!

As you can see the handles are still looking a bit rough, but that is because I ran out of shop time, when i get a minute a nice rub down on the rosewood handles and the a lovely varnish will do the trick!

I have linked to this image as i thought it was too big.

http://www.freewebs.com/simonswoodwork/record/05072008014.jpg

THE RESULT! *

A nice pile of shavings!

Lots of pics here, just thought I'd share as many other people on the forum do too! Any questions or comments just add onto the topic on PM me.

Thanks,

Simon.