DuncanA

Established Member

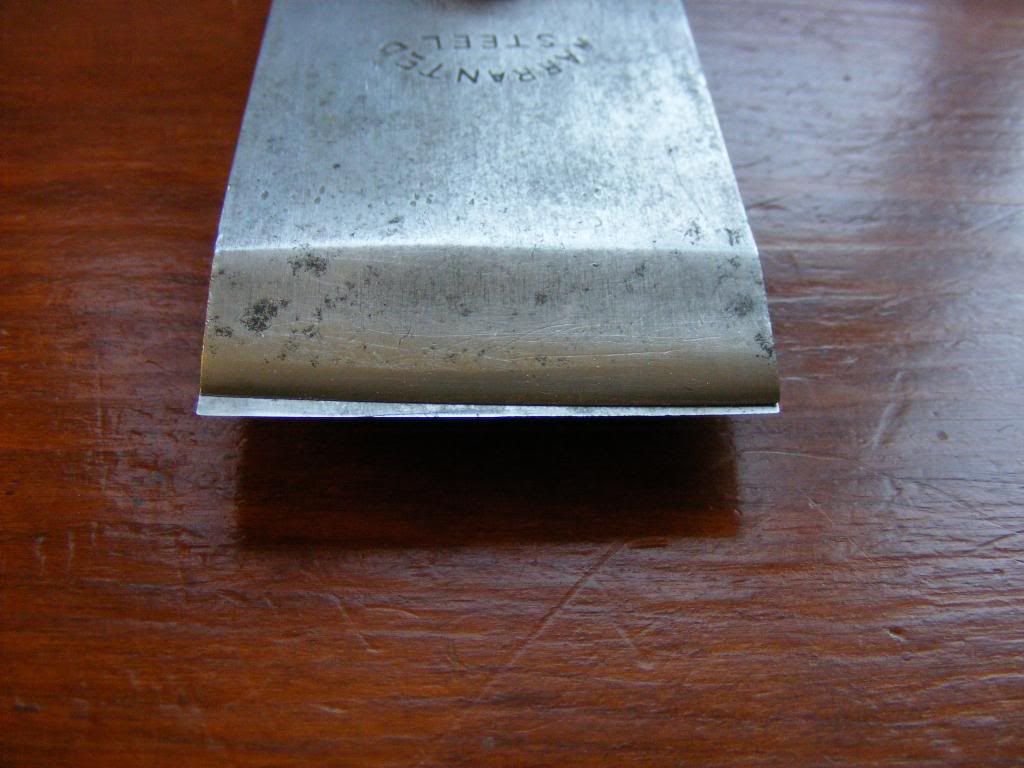

I've been struggling with a back-iron on one of my wooden planes, somewhere in it's life it's picked up a skew so that one side is over 1/16 in. further back from the blade edge than the other, and it tends to pinch shavings and clog. My current efforts (though my lack of experience and courage to change too much may be at part to blame here) have done little to improve things. The blade itself (S. Ashton, Sheffield) seem very good, I know there's room for improvement in my sharpening but I can get it taking nice shavings even from end grain, and it holds the edge well.

I'm starting to wonder if it might be easier to just replace it (just the back-iron probably). I've also got a couple of other planes that could be perfectly usable if they had a new double-iron set. While I can find replacement irons and back-irons for bailey style planes I can't find anything similar for woodies.

Is it possible to get replacement irons for old wooden planes, or does it cause trouble with the taper of the wedge etc.? Presumably they must be available for the few hobbyists and craftsmen who still make wooden planes.

Or is it easier just to try and get a whole new plane? I'm also looking for a new iron for a metal no.4 but a new iron could cost £40+ when I can probably pick up another complete vintage no.4 in good condition for under £20 - I expect the situation will be similar for wooden planes. Though regarding woodies it seems a shame to give up on an old tool that has so much life potentially to give but for one weak link.

I'm starting to wonder if it might be easier to just replace it (just the back-iron probably). I've also got a couple of other planes that could be perfectly usable if they had a new double-iron set. While I can find replacement irons and back-irons for bailey style planes I can't find anything similar for woodies.

Is it possible to get replacement irons for old wooden planes, or does it cause trouble with the taper of the wedge etc.? Presumably they must be available for the few hobbyists and craftsmen who still make wooden planes.

Or is it easier just to try and get a whole new plane? I'm also looking for a new iron for a metal no.4 but a new iron could cost £40+ when I can probably pick up another complete vintage no.4 in good condition for under £20 - I expect the situation will be similar for wooden planes. Though regarding woodies it seems a shame to give up on an old tool that has so much life potentially to give but for one weak link.