Manglitter, that button looks a bit strange to my eye, a bit too tall and not quite long enough.

I'm sure it'll work fine, but I'd expect a buttons to look more like this for simple, functional variants,

Or like this for something more elegant

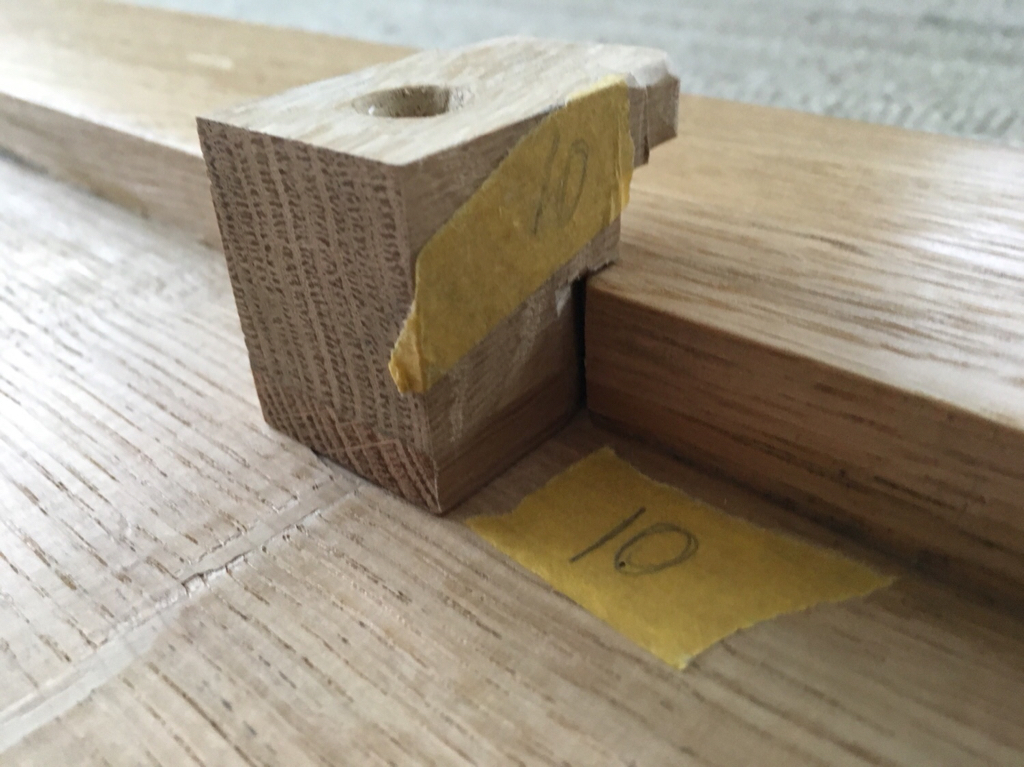

However, both of these buttons would be cut from a board that's say 14mm thick, the bottom edge of the button mortice would be about 14.5mm or 15.0mm from the top edge of the apron rail, the button itself would be around 35 or 40mm long and about 20mm wide. The mortice would be about 25mm wide (so 5mm of play with a 20mm wide tongue on the button) and 6-8mm both high and deep. The net result is that the button rests both on the tongue and on it's heel, but the screw is attempting to "bend" the button ever so slightly to impart some small spring pressure to hold the top reasonably snug against the apron rail.

I'd also ensure that some buttons had been pushed out as far as possible towards the legs in the corner. In almost every case, over time the top will try and cup upwards at the corners, and

this applies no matter what you do with the grain arrangement of the top boards. There's been a few different theories about why this is the case, but if you look at antique furniture, or even any exposed floorboards in your home or the decking in your garden, you'll see this effect in action. Consequently buttons need to be arranged to resist this, just as much as they do to accommodate shrinkage and expansion.