Cheers Coley, sorry not been on earlier, quite a lot of rain so only got out with camera later in afternoon. "I'd save your donations for a milestone. " Yes with you on that, why not.

The stone cill extends 6 inches out from base of what passes for a cill. Attaching several photos of what I've got in my 1930s semi at the moment.

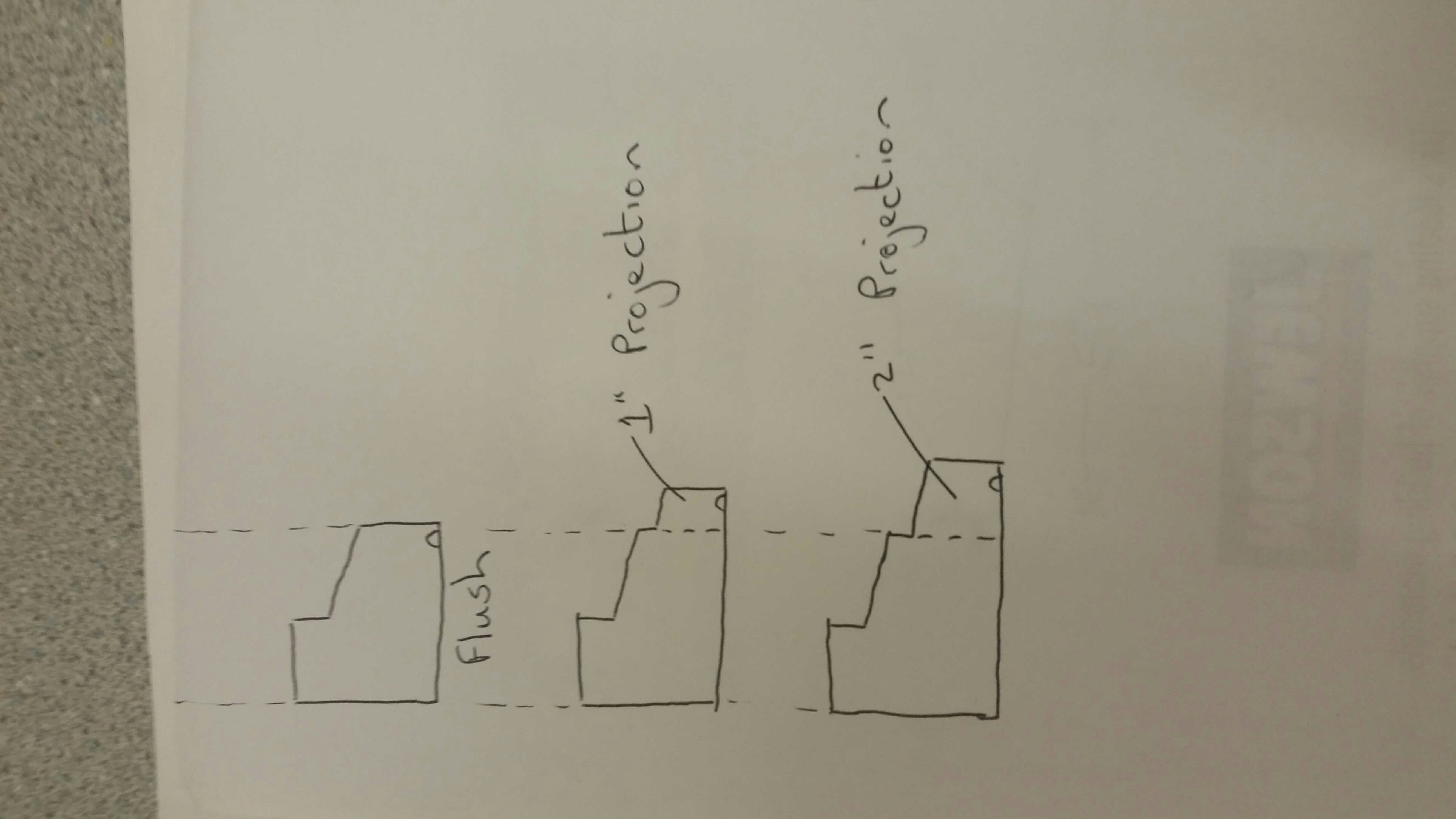

Photo A is ground floor lounge, B a closer view, stone cill and external brick work should clean up with my pressure washer that I got for cleaning up the fence. Do a little pointing should look quite tidy. I had played with the idea of removing the stone cill, then run a course of suitable bricks bit like next door but one, did with their plastic. Then place the new frame forward onto the outer course. Have included photos of next door and next door but one. Photo titled,window style photo is of next door but ones plastic, this is the design style I've decide to use for my replacements. Photo C is ground floor hall, not very keen of having ears in cill, ( I think ears are the correct joinery term ) Photo C window to be replaced with a style like in photo ground floor style A1 but flush not storm.

Next doors have same size window openings as mine.

" The other question is would you prefer a relatively thin frame 57mm (more light perhaps) or a chunkier 69mm frame ? "

Uum has the obvious attraction to me as could be less expense. Then again would a chunkier frame look better. A lighter frame could be a consideration as I'll be on my scaffold tower contriving to pull the frame up on a rope. I was having a ponder about this manoeuvre the other night, how I'm going to go about doing it. When I was on the tower, bodge fixing one of the cills and putting masonary paint on. How the tower had to be positioned, was a gap between wall and tower, occurred to me just increase the gap and pulling the frame should be straightforward. My best mate is a roofer, tiler and plasterer and quite a bright spark, will ask if he has any additional ideas on getting frame up and into position, but is only a one man tower. Oh, and the lounge ground floor window opening is 57" x 57" side ground floor 42" x 36"

Any suggestions, ideas, folks?