Hi All

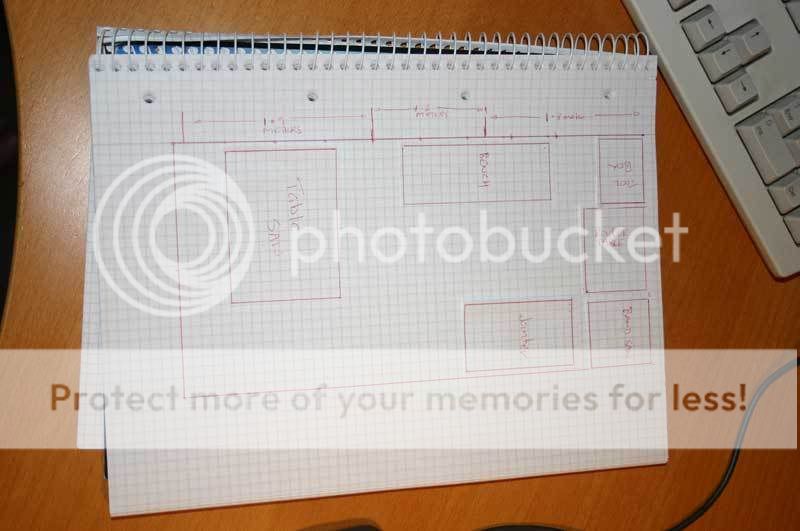

With all this workshop construction going on and me planning a workshop as well I would like to ask the experienced woodworkers on the forum as to their best advice for workshop layouts, positioning of larger machine tools, benches and storage. I know in kitchens there is the work triangle of the fridge, cooker and sink, is there a similar rule in the workshop.

Any thoughts please

With all this workshop construction going on and me planning a workshop as well I would like to ask the experienced woodworkers on the forum as to their best advice for workshop layouts, positioning of larger machine tools, benches and storage. I know in kitchens there is the work triangle of the fridge, cooker and sink, is there a similar rule in the workshop.

Any thoughts please