wizer

Established Member

- Joined

- 3 Mar 2005

- Messages

- 15,589

- Reaction score

- 1

wizer":1h6f7sbp said:I think it burn very quick with a lot of smoke. You need to combine it with real wood I guess.

katellwood":e4o0bq42 said:I appreciate this can be done with news/wastepaper and card but can planer chippings and sawdust be turned into logs/briquettes without the use of an industrial press

OPJ":2dfmeurg said:You just need something like peat

wizer":3trvbhou said:hahah that'll have the environMentalists up in arms

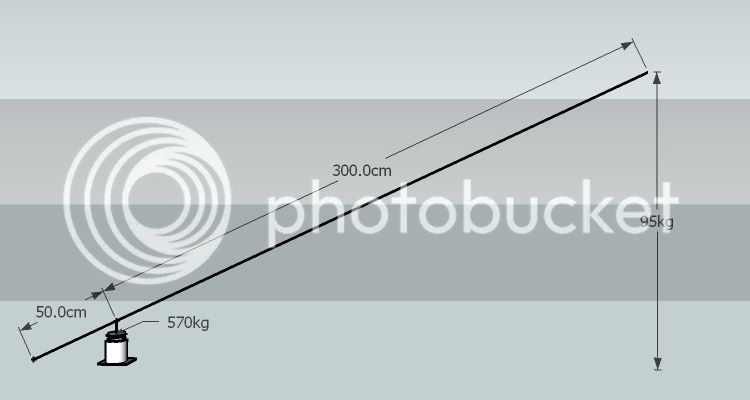

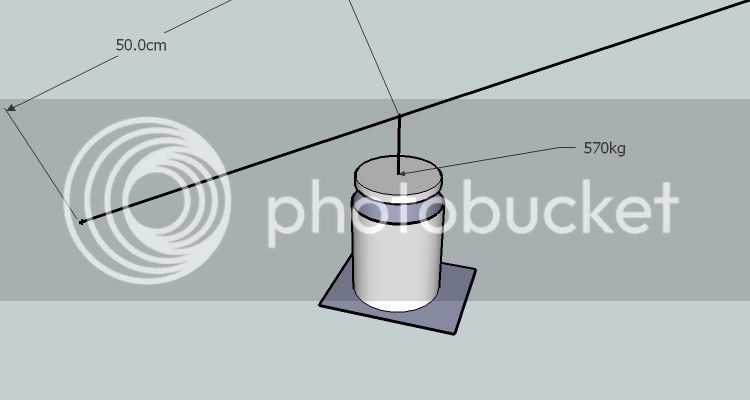

BMac":31rhqhhc said:siting the work close to the fulcrum is difficult because the end of the lever is so high up

Enter your email address to join: