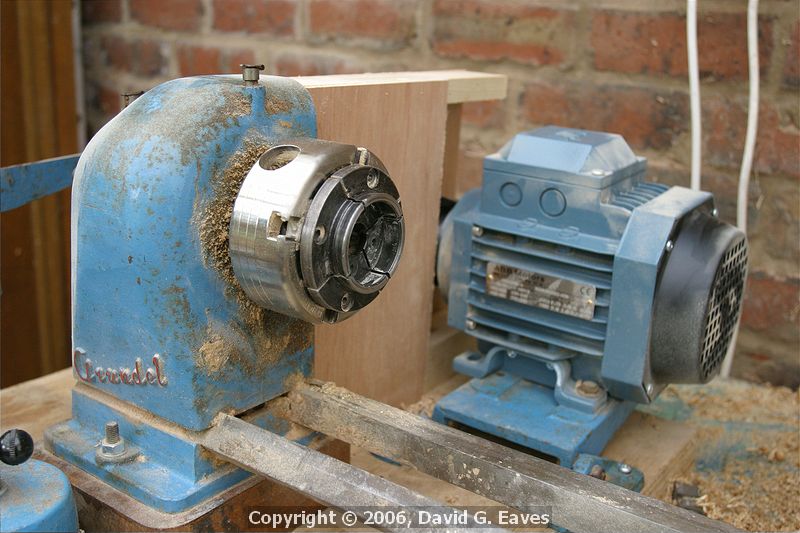

Fascinating. I'm just in the throes of trying to convert an old RPML300 lathe to variable speed, but trying not to spend more than it is worth doing it. So I've got a 1/2horse 3-phase motor for a tenner off Ebay, and am collecting a £20 inverter from the 'bay later this week. Then it's just the little matter of extending the shaft of the motor, wiring up the inverter and finding a suitable enclosure.......... Good job I'm not costing my time.

David - is there any ventilation into your enclosure? For the RPML, I was going to make up a box like your's, but with a computer fan and a filtered air intake. Any thoughts?

Also interesting to note that the Arundel J4 has the same arrangement of bed bars (one square, one edge on) to the Avon. I wonder if Tyme copied the idea? The last Arundels were super lathes, especially the K600, but limited by the absence of a swivelling head. I guess that's one reason why Record dropped them as soon as they bought out Arundel.