This is a small (5 foot tall) bookcase I have nearly finished. Inspired by an open frame design for a corner cupboard by James Krenov (the fine art of cabinet making ISBN 0-8069-8572-0, page 170). The material is American White Oak, with a hand rubbed oil finish. The frame is mortice and tennon, with through joints at four locations on front (and rear) of the frame. The cupboard has dovetail corners forming the carcase, an applied back (with baise lining inside), and veneered doors (veneer made from stock cut on tablesaw). Adjustable shelves are supported on movable bars set into the carcase sides.

My favourite shop ? Choosing the wood.

Frame assembled to check prior to glue up. (Note shoes to protect feet).

Getting some help from my assistant.

Through tenon at top of frame.

Through tenon at bottom of frame.

Plano glue press - pressing home made veneer onto plywood base to form the doors. The doors were made together in one piece which was then cut down the middle, ensuring the two doors meet dead straight in the middle when shut.

Fitting the case to the frame. You can see the movable shelf bar supports at the rear of the carcase.

Detail of the dovetails on one corner of carcase.

Better view of shelf support cut outs.

Got the doors on - fine fitting.

Doors oil finished & brass hardware in place.

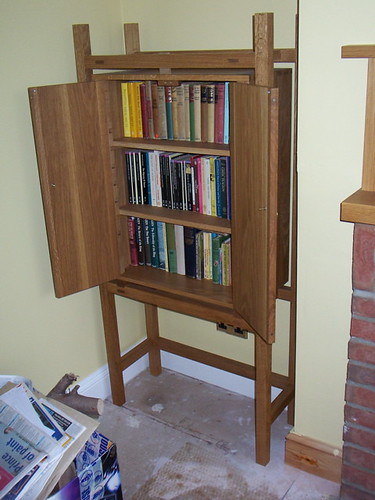

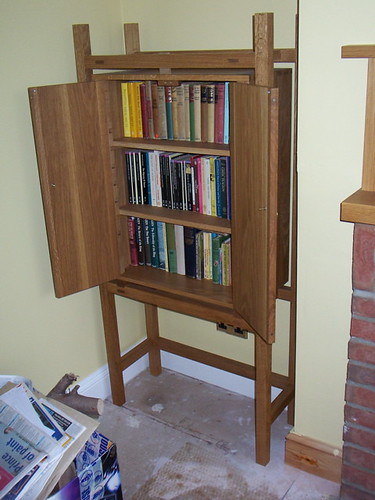

Full of books already ! note pin in top of case - this pin and two through base of carcase into frame, is all that holds the carcase into the frame.

Good pic of the finished bookcase (matches fireplace overmantel).

All done ! SWMBO approves. Now I've just got to make the one for the other alcove . . .

Regards Catface.

My favourite shop ? Choosing the wood.

Frame assembled to check prior to glue up. (Note shoes to protect feet).

Getting some help from my assistant.

Through tenon at top of frame.

Through tenon at bottom of frame.

Plano glue press - pressing home made veneer onto plywood base to form the doors. The doors were made together in one piece which was then cut down the middle, ensuring the two doors meet dead straight in the middle when shut.

Fitting the case to the frame. You can see the movable shelf bar supports at the rear of the carcase.

Detail of the dovetails on one corner of carcase.

Better view of shelf support cut outs.

Got the doors on - fine fitting.

Doors oil finished & brass hardware in place.

Full of books already ! note pin in top of case - this pin and two through base of carcase into frame, is all that holds the carcase into the frame.

Good pic of the finished bookcase (matches fireplace overmantel).

All done ! SWMBO approves. Now I've just got to make the one for the other alcove . . .

Regards Catface.