Hi All

First off what a great forum with some excellent work.

I am looking to construct a hardwood gate if possible as the prices i have had quoted are out of my budget, in excess of £500 !!!!

I am a novice when it comes to woodworking but have access to all tools ie router, mitre saw etc.

I am looking to construct a hardwood pedestrian gate out of Meranti if possible.

Looking for it to be 2 1/2" to 3" thick, with hardwood posts to match.

Is this out of my capability as a novice ? Anybody got any plans for this style of gate ??

I have also toyed with the idea of purchasing a cheap softwood made to measure ledge/brace door and fixing hardwood tongue/groove cladding to the front - http://decksupply.co.uk/19_x_135mm_Tong ... ding_.aspx

Is this feasible ????

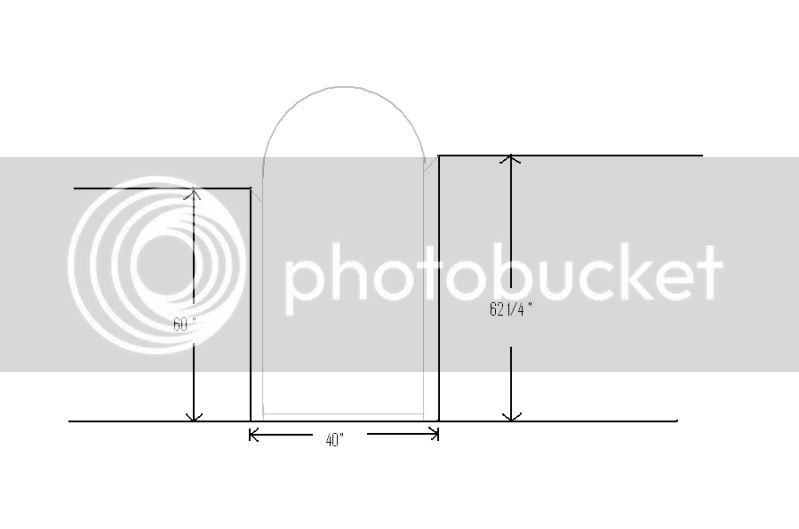

Pics for general idea of style gate and my opening/dimensions.

If anyone can help in any way it will be much appreciated as i am at a dead end at the moment and can not find any craftsmen in my area to help....

Thanks

First off what a great forum with some excellent work.

I am looking to construct a hardwood gate if possible as the prices i have had quoted are out of my budget, in excess of £500 !!!!

I am a novice when it comes to woodworking but have access to all tools ie router, mitre saw etc.

I am looking to construct a hardwood pedestrian gate out of Meranti if possible.

Looking for it to be 2 1/2" to 3" thick, with hardwood posts to match.

Is this out of my capability as a novice ? Anybody got any plans for this style of gate ??

I have also toyed with the idea of purchasing a cheap softwood made to measure ledge/brace door and fixing hardwood tongue/groove cladding to the front - http://decksupply.co.uk/19_x_135mm_Tong ... ding_.aspx

Is this feasible ????

Pics for general idea of style gate and my opening/dimensions.

If anyone can help in any way it will be much appreciated as i am at a dead end at the moment and can not find any craftsmen in my area to help....

Thanks