jack55

Established Member

I have gleaned a lot of information regarding the building of workshop sheds from this forum so I have decided to post my new build worksho, some other beginner my find it useful.

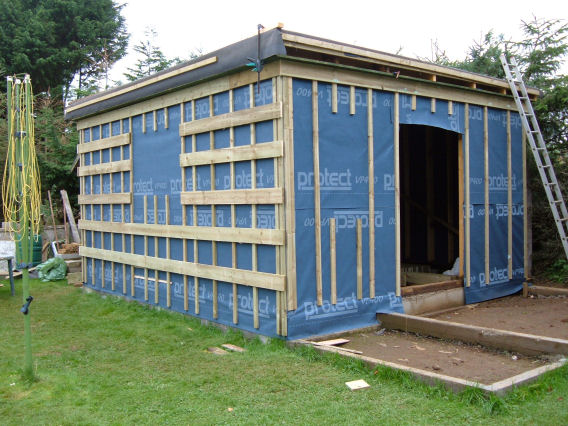

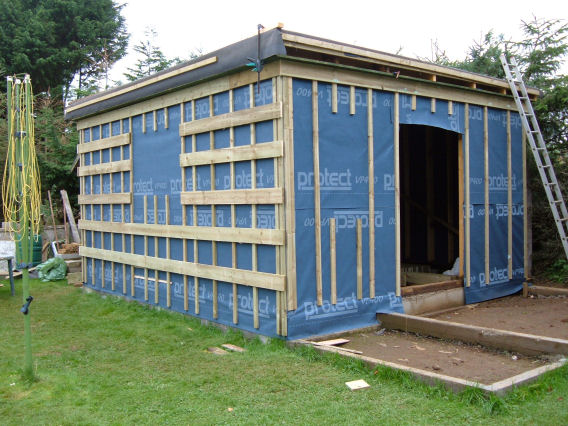

I knocked down my old shed as it was cold and too small and started to build a new one last summer. Decided against a concrete floor, partly down to the location where the new one is and all the wheel barrowing of ballast sand and concrete, plus i wanted to use as much of the timber from the old shed as I could. this one is 18ft by 14ft

Had to build the frame in sections so I could handle it. Did the corners first

Made up some venting boards to allow air to circulate over the roof insulation, although there will be an air gap behind the boarding which is why theres a gap between the board and the frame.

The roof is a flat roof, with 4" polystyrene insulation sitting between the joist, with the firings on top there is more than the recommend 50mm gap above the insulation and on top of the joists is a breathable membrane, then 18mm OSB, one layer of felt and then full length steel roofing sheets. The flat roof keeps me under the planning requirement and gives me plenty of headroom.

The Horizontal batterns are because I decided to use board and battern cladding. The reason for this was, price and convenience, 18mm ship lap T&G was £2/mtr (£900 worth needed) and it is untreated, which given the time of year it would be going on it would get wet before it could be painted and would take months to dry out. The boards were 80p/mtr, 25mm thick and are treated, being rough sawn they also take the finish better.

The floor is similar the roof, joists with a breathable membrane on top then 18mm chipboard T&G, followed by batterns and 2" polystyrene insulation, a vapour barrier and then another layer of 18mm T&G chip board.

Three of the walls are insulated with loft insulation as it was being sold for less than a pound a square metre, the wall opposite the door has 4" of polystyrene as I had enough left over. The polystyrene was a good buy from an ebay shop. The walls and roof are cover in a vapour barrier and then 12 mm OSB.

Then gallons of paint

The window glass is from a double glazed frame which I picked up for £20. I did have a debate with myself on the merits of windows verses the need for warmth.

As it stands at the moment I was able to work inside during the winter with a temporary elecy supply and only had the 2KW heater on half setting, which given the temperatures we had was pretty good, the reverse of that, is it is also cool when the sun is out, over the last week while it has been 20 plus outside it has been a lot cooler inside the shed.

I still have the electrics to do and have buried 10mm amoured cable from the house to the shed ready to fit a consumer unit and sockets and lights. Just need to find a supplier of 6ft double probably 70w fluorescent lights, all the ones I have found so far on the web are out of stock. There is also some flagging to do in front of the door to provide and area to work outside when the mood takes me.

Once the electrics are in I can start to fit out the inside.

I knocked down my old shed as it was cold and too small and started to build a new one last summer. Decided against a concrete floor, partly down to the location where the new one is and all the wheel barrowing of ballast sand and concrete, plus i wanted to use as much of the timber from the old shed as I could. this one is 18ft by 14ft

Had to build the frame in sections so I could handle it. Did the corners first

Made up some venting boards to allow air to circulate over the roof insulation, although there will be an air gap behind the boarding which is why theres a gap between the board and the frame.

The roof is a flat roof, with 4" polystyrene insulation sitting between the joist, with the firings on top there is more than the recommend 50mm gap above the insulation and on top of the joists is a breathable membrane, then 18mm OSB, one layer of felt and then full length steel roofing sheets. The flat roof keeps me under the planning requirement and gives me plenty of headroom.

The Horizontal batterns are because I decided to use board and battern cladding. The reason for this was, price and convenience, 18mm ship lap T&G was £2/mtr (£900 worth needed) and it is untreated, which given the time of year it would be going on it would get wet before it could be painted and would take months to dry out. The boards were 80p/mtr, 25mm thick and are treated, being rough sawn they also take the finish better.

The floor is similar the roof, joists with a breathable membrane on top then 18mm chipboard T&G, followed by batterns and 2" polystyrene insulation, a vapour barrier and then another layer of 18mm T&G chip board.

Three of the walls are insulated with loft insulation as it was being sold for less than a pound a square metre, the wall opposite the door has 4" of polystyrene as I had enough left over. The polystyrene was a good buy from an ebay shop. The walls and roof are cover in a vapour barrier and then 12 mm OSB.

Then gallons of paint

The window glass is from a double glazed frame which I picked up for £20. I did have a debate with myself on the merits of windows verses the need for warmth.

As it stands at the moment I was able to work inside during the winter with a temporary elecy supply and only had the 2KW heater on half setting, which given the temperatures we had was pretty good, the reverse of that, is it is also cool when the sun is out, over the last week while it has been 20 plus outside it has been a lot cooler inside the shed.

I still have the electrics to do and have buried 10mm amoured cable from the house to the shed ready to fit a consumer unit and sockets and lights. Just need to find a supplier of 6ft double probably 70w fluorescent lights, all the ones I have found so far on the web are out of stock. There is also some flagging to do in front of the door to provide and area to work outside when the mood takes me.

Once the electrics are in I can start to fit out the inside.