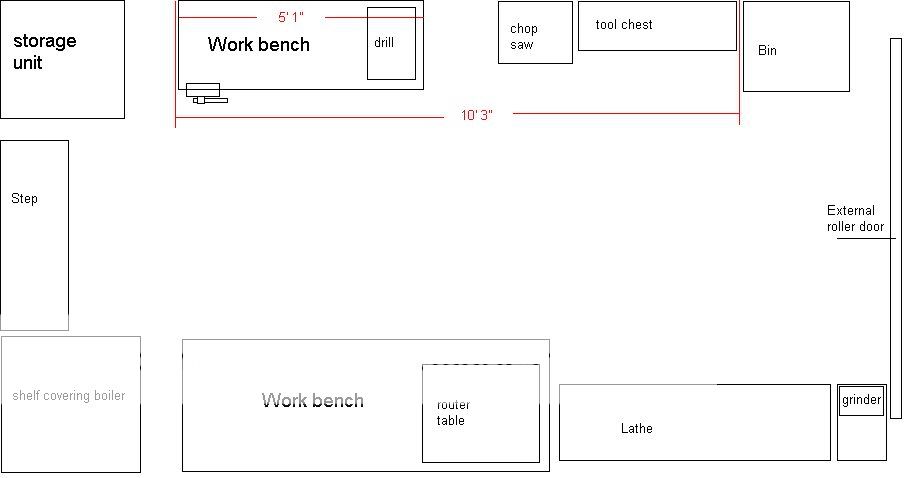

I'm currently working in my integral garage. Works well for me but I'm getting more machinery and I need a good solid work bench. So, in January I'm going for a complete workshop refit. Everything out - clean up/paint etc then everything back in, in a proper order.

My question is, I currently have a workspace for siting at and doing sit down jobs its a 5' worksurface, at the side of it is a 5' space where my power saw sits. I have recently been up to my friends timber yard for a family visit (took the long wheelbase transit van though just in case!!) and returned with 12 x 10' scaffold planks and a load of 10' peices of 4"x4". So I had an idea. I shall build me a 5' woodwork bench in the space...

...or should I leave the planks whole and rip out the exsisting work surface and just build a 10' work bench?

I figure I could open a 10' space up, butt join the planks and make me a 10' x 2' work area which I could stand my saw on one end, pillar drill in the middle and fit a wood bench vice too. Using the 4"x4" posts, I could make 6 legs and the relevant strengthening struts.

any thoughts?? I'll try post a plan real soon.

PS: When I start this I will thoroughly document. (with pictures).

My question is, I currently have a workspace for siting at and doing sit down jobs its a 5' worksurface, at the side of it is a 5' space where my power saw sits. I have recently been up to my friends timber yard for a family visit (took the long wheelbase transit van though just in case!!) and returned with 12 x 10' scaffold planks and a load of 10' peices of 4"x4". So I had an idea. I shall build me a 5' woodwork bench in the space...

...or should I leave the planks whole and rip out the exsisting work surface and just build a 10' work bench?

I figure I could open a 10' space up, butt join the planks and make me a 10' x 2' work area which I could stand my saw on one end, pillar drill in the middle and fit a wood bench vice too. Using the 4"x4" posts, I could make 6 legs and the relevant strengthening struts.

any thoughts?? I'll try post a plan real soon.

PS: When I start this I will thoroughly document. (with pictures).