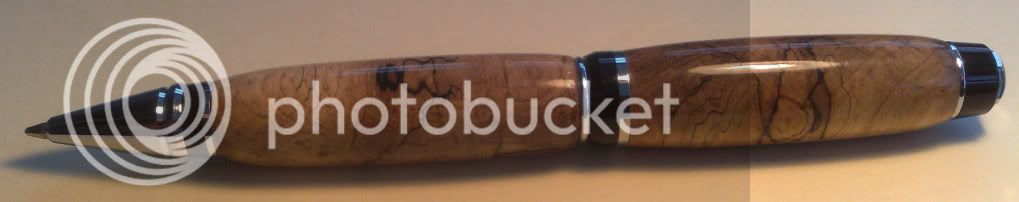

well i got time today to try one of the blanks we got from neil. ( thanks neil ) it is a x cut spalted hard maple on a cigar pen kit for the son in law.

there were no blow outs because you must use super sharp tools and also keep stabalising the blank with thin ca. but once its done i micromeshed up to 12000 then i used ca/blo( 4 coats ) what dya think ? well i like the result and so does the s.i.l.

there were no blow outs because you must use super sharp tools and also keep stabalising the blank with thin ca. but once its done i micromeshed up to 12000 then i used ca/blo( 4 coats ) what dya think ? well i like the result and so does the s.i.l.