So I was looking for a bandsaw recently as I've had many situations where one would have been real dandy. I found a small INCA for sale but the seller never bothered responding. So I put up my own wanted ad and I had plenty of responses, but the most intriguing one was from a boat building company up north. To make a short story shorter, I bought it, €200 + shipping which was 60+VAT, I had to pay another guy here with a tractor another 20 to get it inside the garage because there was no way I was getting this inside the shop, three of us where then able to drag it into it's final resting place. I am not sure a mobile base is possible for this saw. I had removed the table as well before moving it.

It is pretty much the opposite kind of machine from the INCA I was looking at first.

I don't know how many hundreds pf kilos this weighs but it's plenty enough. I had to remove the wheel and the whole wheel and blade enclosure, which turned out to be made from plywood and bolted onto the frame. I am pretty sure the saw came without it and it's a later addition due to safety regulations. The saw has a 5.5kw direct drive motor. I can't see the motor plate but the starting equipment says 5.5kw on it so I assume the motor is that. It says VEB on it which I believe is an east german AEG motor.

The brand of the saw is a Göteneds from what we've been able to tell, which is a swedish made saw, they stopped making bandsaws in 1960 so this is no younger than 54 years old, likely older still though.

The motor runs real smooth and quiet when I tested it, also takes forever to spin down but it has a brake lever. The lower wheel has a noticeable wobble to it and the saw shakes a little bit. I am not sure how to correct it, is it the wheel itself, or is the motor shaft not true. Matthias Wandel has a video on tuning up a small band saw and he shimmed the motor mounts to compensate for the wobble.

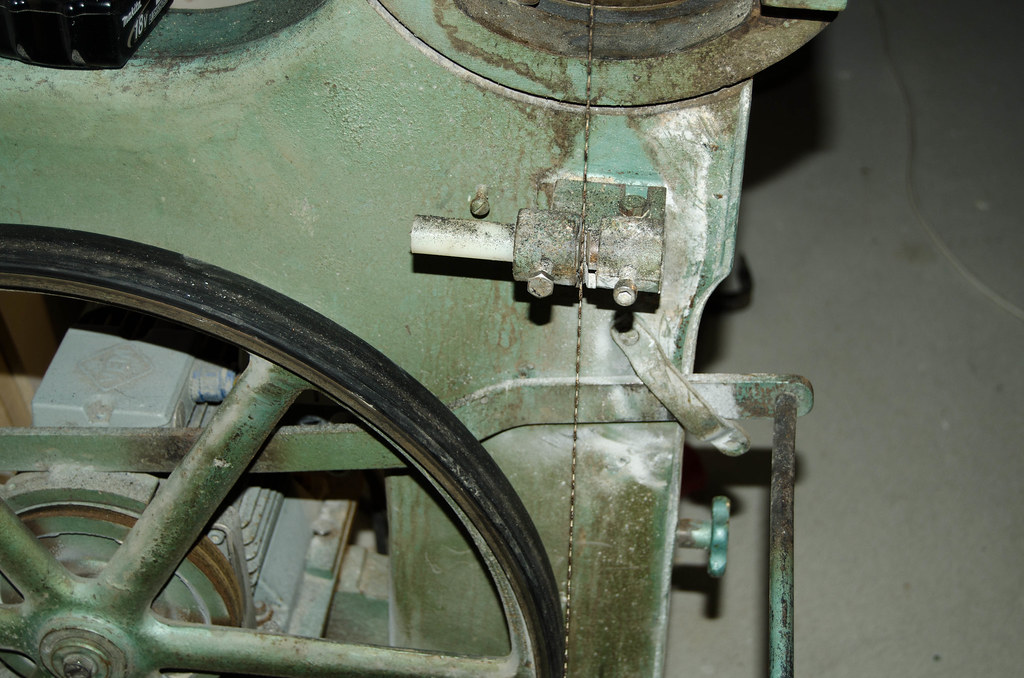

The blade guides are simple but if they work I do not care. There's a piece of wood on one side and a piece of brass on the other I believe. Strange setup...

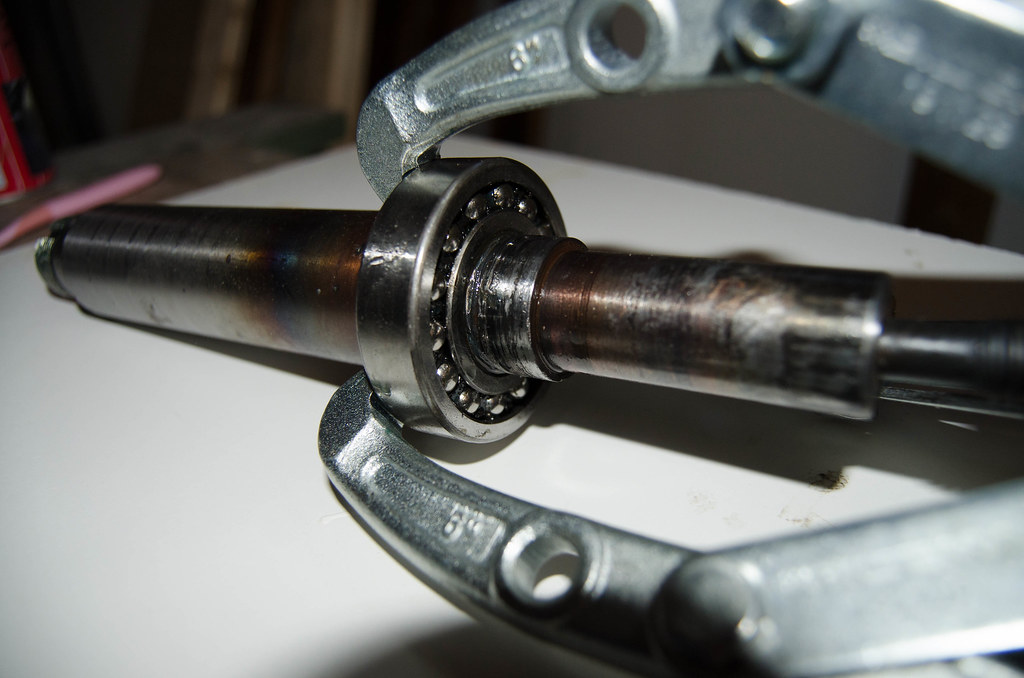

I committed an error trying to get the upper wheel off and tried to remove the whole shaft with bearings but that was a mistake. The bearing on one end is smaller than the hole on the other side so it is held captive so to speak. The worst thing is I cannot get it back into the holder on the other side. The bearing on that end of the shaft is supposed to fit in there but I have tried for hours today to get it back, no luck. I am wondering if I can remove the whole tensioning apparatus and take it to a machine shop and they can fix it for me. It is lifted and lowered via hydraulics. I am not sure if it can just be lifted off...

The "holder" into which the bearing needs to be pressed:

It is pretty much the opposite kind of machine from the INCA I was looking at first.

I don't know how many hundreds pf kilos this weighs but it's plenty enough. I had to remove the wheel and the whole wheel and blade enclosure, which turned out to be made from plywood and bolted onto the frame. I am pretty sure the saw came without it and it's a later addition due to safety regulations. The saw has a 5.5kw direct drive motor. I can't see the motor plate but the starting equipment says 5.5kw on it so I assume the motor is that. It says VEB on it which I believe is an east german AEG motor.

The brand of the saw is a Göteneds from what we've been able to tell, which is a swedish made saw, they stopped making bandsaws in 1960 so this is no younger than 54 years old, likely older still though.

The motor runs real smooth and quiet when I tested it, also takes forever to spin down but it has a brake lever. The lower wheel has a noticeable wobble to it and the saw shakes a little bit. I am not sure how to correct it, is it the wheel itself, or is the motor shaft not true. Matthias Wandel has a video on tuning up a small band saw and he shimmed the motor mounts to compensate for the wobble.

The blade guides are simple but if they work I do not care. There's a piece of wood on one side and a piece of brass on the other I believe. Strange setup...

I committed an error trying to get the upper wheel off and tried to remove the whole shaft with bearings but that was a mistake. The bearing on one end is smaller than the hole on the other side so it is held captive so to speak. The worst thing is I cannot get it back into the holder on the other side. The bearing on that end of the shaft is supposed to fit in there but I have tried for hours today to get it back, no luck. I am wondering if I can remove the whole tensioning apparatus and take it to a machine shop and they can fix it for me. It is lifted and lowered via hydraulics. I am not sure if it can just be lifted off...

The "holder" into which the bearing needs to be pressed: