devonwoody

Established Member

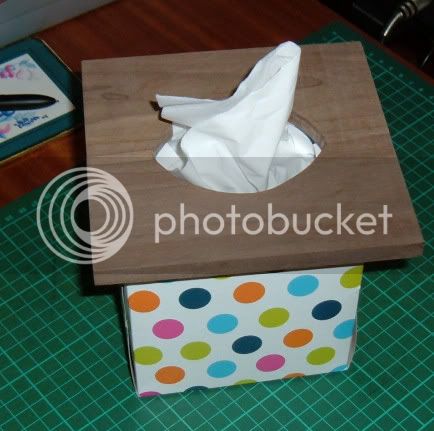

New shape box and a change of style coming up.

Located this length of Oak with an unusual grain pattern and it it just long enough for two boxes if I make those reverse mitre corner joints instead of the conventional type. This is because the longest length goes to the internal face of the box and does not lose length because of a conventional joint.

It is 15 mm thick which is a bit heavy for a tissue box so put it through the thicknesser 6 times (three each face) and reduced to about 9.80mm.

Then drew up a pattern piece.

and did this.

Enough for one box, (hence the title dotty box)

Going to turn three different colour spindles to around 15mm diameter

and plug those holes.

Located this length of Oak with an unusual grain pattern and it it just long enough for two boxes if I make those reverse mitre corner joints instead of the conventional type. This is because the longest length goes to the internal face of the box and does not lose length because of a conventional joint.

It is 15 mm thick which is a bit heavy for a tissue box so put it through the thicknesser 6 times (three each face) and reduced to about 9.80mm.

Then drew up a pattern piece.

and did this.

Enough for one box, (hence the title dotty box)

Going to turn three different colour spindles to around 15mm diameter

and plug those holes.