Stimpi

Established Member

Weekends since last year have been helping my daughter on her allotment. This year started by repairing wind damage not helped by the continuous rain.

The greenhouse I built survived well until the high winds of Valentines Day when it was hit by a part from shed from elsewhere on the allotment.

A lot of the sheds and greenhouses suffered damage mainly due to poor foundations or lack of and poor repair. Hence a Dunkirk spirit prevailed and a big clear up was the order of the day. The long and short of it all is we acquired enough parts to build our own shed with the exception of a floor.

I levelled a suitable area, selected an aspect that gave the best light, collected sufficient paving slabs and bricks resulting in building a solid support for the shed floor. 4” x 2” was salvaged for the joists with the intention of spacing them at 16” centres but I could not find sufficient for this so decided on 24” centres. DOH! I was purchasing new floor boards from Wickes who have a special offer on at present. I had forgotten about waste and the rule “The cut board is the next one to lay” the resultant waste on 24” centres amounted to an extra pack of boards. I had noticed a skip on the way in (after purchasing the flooring). Spoke to the owner who let me take some redundant 4” x 2” which saved the day..

I find it easier in levelling a base to level four corners with two stretchers and then put cross joists at right angles, lay the floor to its exact size trimming any excess. I then placed paving slabs at 32” centres packing up with two course of bricks and if required some slate packing. The boarded floor could be lifted with a fulcrum point and the tile slipped in.

The following weekend the sides and roof all erected, bolted up and the jobs a gudun. What I need now is a door.

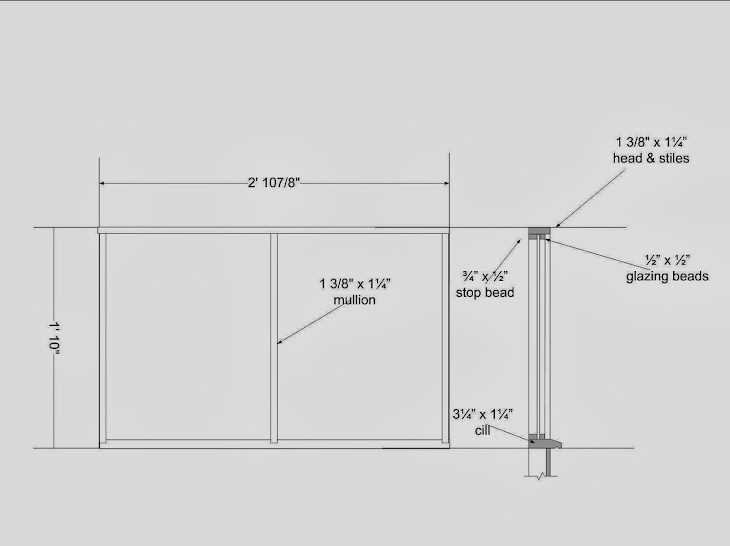

A visit to the local Garden Centre to see what’s on offer. £800.0 for a potting shed makes for expensive carrots. I new this, I was more interested in what doors they supplied. The deluxe model was advertised as a Frame Ledged and Braced door but in my opinion its not. Shed door construction has been a re-occurring post and would be of interest to other woodworkers. Despite what it is will it be fit for purpose as it would be relatively easy to make? There are other issues. Do I make a door frame so it opens inwards?

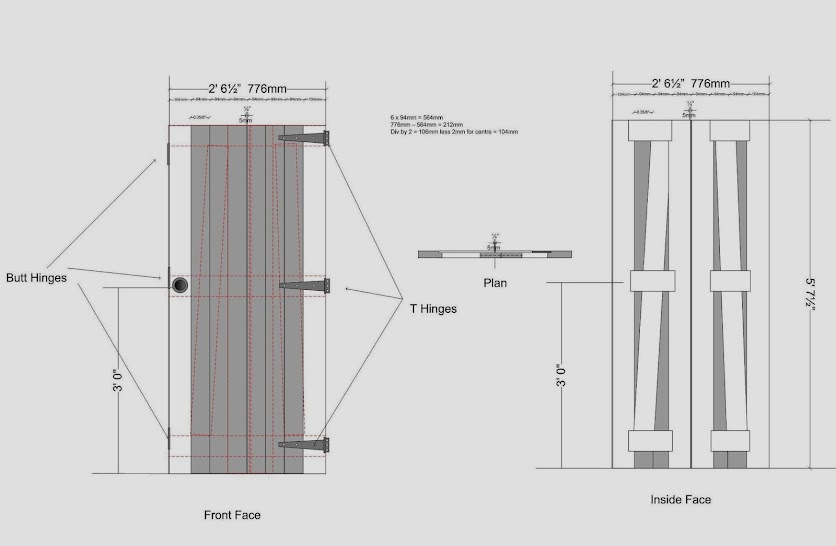

Here is the inside view.

And the edge view.

The greenhouse I built survived well until the high winds of Valentines Day when it was hit by a part from shed from elsewhere on the allotment.

A lot of the sheds and greenhouses suffered damage mainly due to poor foundations or lack of and poor repair. Hence a Dunkirk spirit prevailed and a big clear up was the order of the day. The long and short of it all is we acquired enough parts to build our own shed with the exception of a floor.

I levelled a suitable area, selected an aspect that gave the best light, collected sufficient paving slabs and bricks resulting in building a solid support for the shed floor. 4” x 2” was salvaged for the joists with the intention of spacing them at 16” centres but I could not find sufficient for this so decided on 24” centres. DOH! I was purchasing new floor boards from Wickes who have a special offer on at present. I had forgotten about waste and the rule “The cut board is the next one to lay” the resultant waste on 24” centres amounted to an extra pack of boards. I had noticed a skip on the way in (after purchasing the flooring). Spoke to the owner who let me take some redundant 4” x 2” which saved the day..

I find it easier in levelling a base to level four corners with two stretchers and then put cross joists at right angles, lay the floor to its exact size trimming any excess. I then placed paving slabs at 32” centres packing up with two course of bricks and if required some slate packing. The boarded floor could be lifted with a fulcrum point and the tile slipped in.

The following weekend the sides and roof all erected, bolted up and the jobs a gudun. What I need now is a door.

A visit to the local Garden Centre to see what’s on offer. £800.0 for a potting shed makes for expensive carrots. I new this, I was more interested in what doors they supplied. The deluxe model was advertised as a Frame Ledged and Braced door but in my opinion its not. Shed door construction has been a re-occurring post and would be of interest to other woodworkers. Despite what it is will it be fit for purpose as it would be relatively easy to make? There are other issues. Do I make a door frame so it opens inwards?

Here is the inside view.

And the edge view.