Sorry been away from computer all weekend, roped into gardening, however I did manage to get some workshop time as you will see below.

Jon, kind offer but can you hold fire till I see how my idea works out.

David ( just finished your "Guide to hand tools and methods" thoroughly enjoyed it thanks) as far as I can determine the new reproductions are enlarged versions of the originals, whether this is just the handles or the whole tool is not clear.

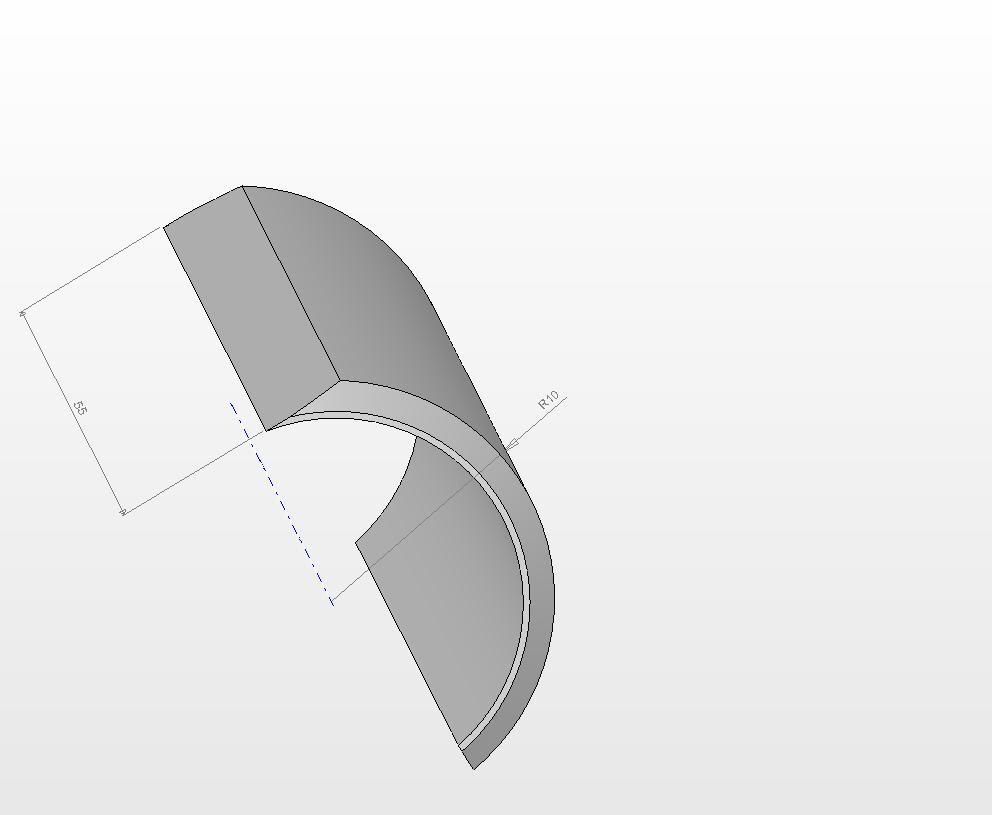

I made a start on building the dies and have actually made a blade albeit of mild steel, just to prove the process whilst I wait for the tool steel to arrive from J+L.

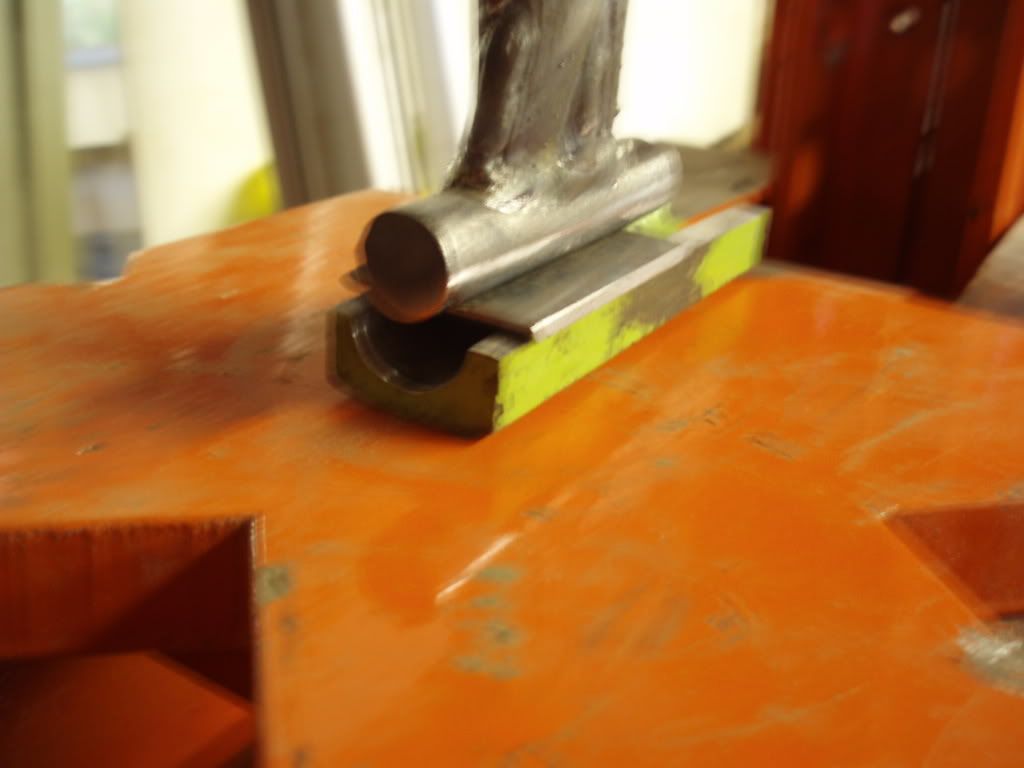

This is the mild steel coupon, prebevelled sides to engage screws on shave. This is 4mm steel I think, thicker than will be used for the real thing.

Set up in the dies on the press.

Out the dies and looking good.

Rough bevel ground and fitted to shave. I did have to lap this to fit but I'm not anticipating this problem with the tool steel which will be thinner, plus I'm going to experiment with shims to get a perfect inner diameter.

Next challenge will be heat treating this without distorting the whole shooting match.