Doug B

Shy Tot

Pick up this poor old tired drill earlier this year

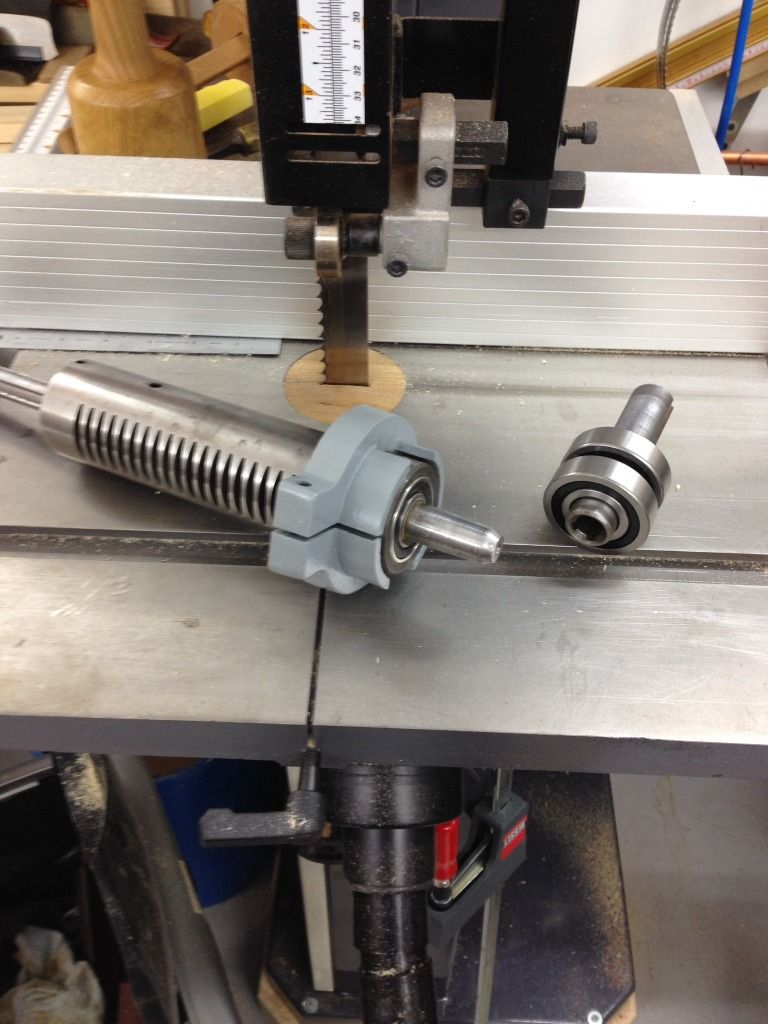

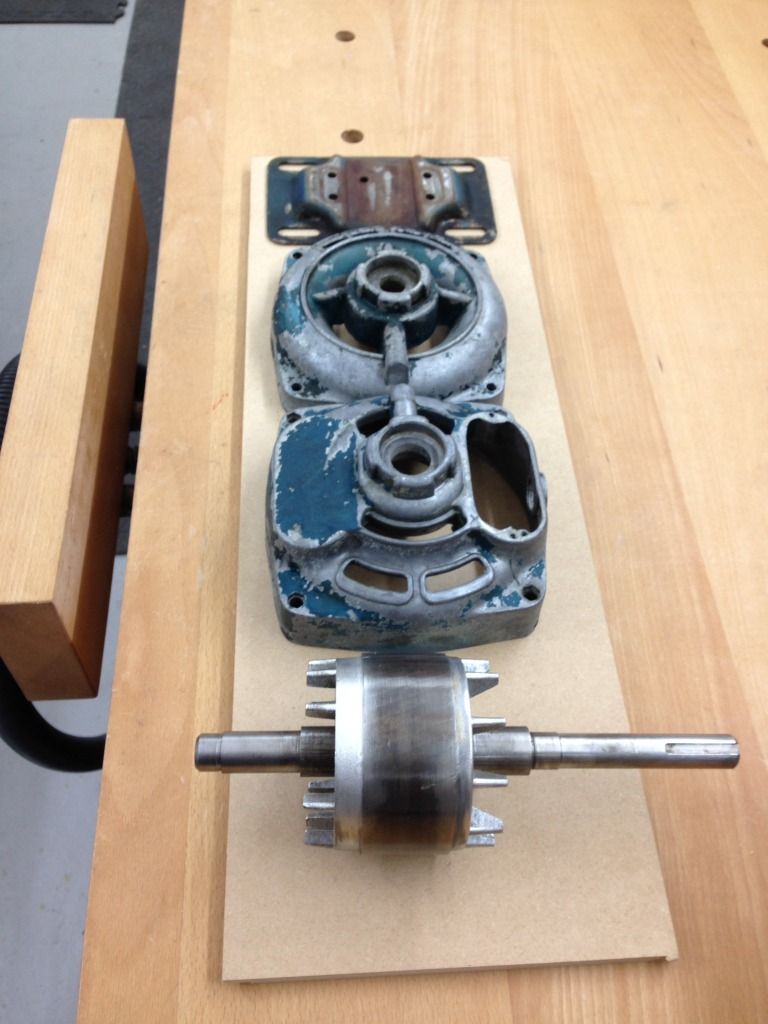

It was pretty grimed up & looked to have had a hard life which included at some point someone painting it cream, but it had very little run out so I thought it would be worth cleaning up. It was single phase though for some reason didn't have an on off switch, it must have been a case of plugging it in to get it to work, not really a problem as I want 3 phase & have managed to pick up a matching 3 phase motor.

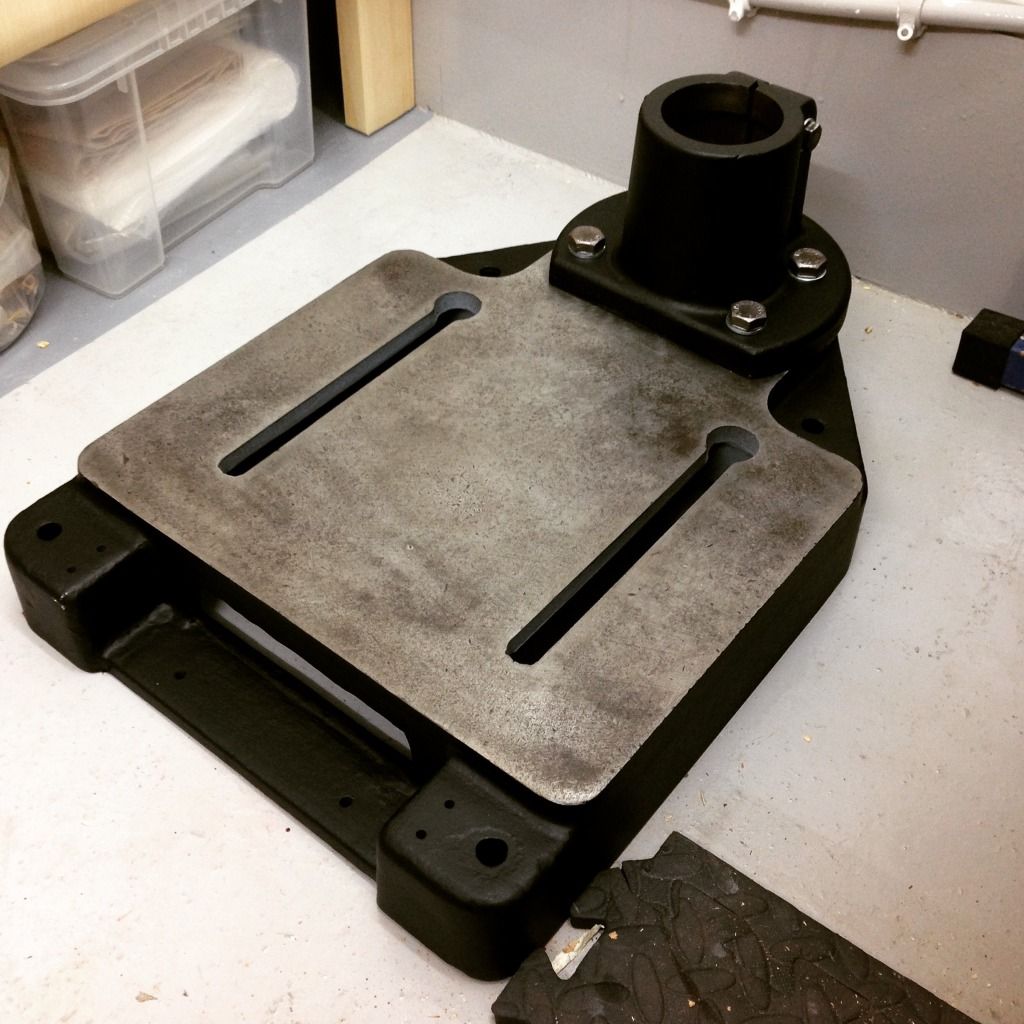

I started by dismantling all the parts & getting them dipped to remove all the grot & grime, this was a few months ago & I've only just managed to get started on it but today I've sanded all the main parts & started spraying them, the base & pillar clamp are the black pieces in the background.

I'm hoping progress on this renovation will speed up considerably over the Xmas break.

It was pretty grimed up & looked to have had a hard life which included at some point someone painting it cream, but it had very little run out so I thought it would be worth cleaning up. It was single phase though for some reason didn't have an on off switch, it must have been a case of plugging it in to get it to work, not really a problem as I want 3 phase & have managed to pick up a matching 3 phase motor.

I started by dismantling all the parts & getting them dipped to remove all the grot & grime, this was a few months ago & I've only just managed to get started on it but today I've sanded all the main parts & started spraying them, the base & pillar clamp are the black pieces in the background.

I'm hoping progress on this renovation will speed up considerably over the Xmas break.