RobertMP

Established Member

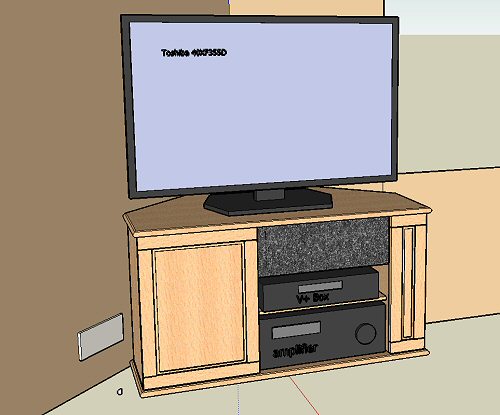

I'm planning on starting on a corner TV stand unit soon. It will need to be dragged out now and then whilst setting up or plugging in things etc so I'd like it to be pretty rigid and stay that way. It will have glider type feet and be on carpet so It shouldn't need excessive force to move it.

I'm thinking of buying a sheet of 12mm oak veneered MDF to make most of it. Top and bottom I was thinking of gluing 6mm plain MDF to the undersides to make those 18mm thick. All the edges will be trimmed with oak and the top and bottom trims profiled to match small tables I made as my first ever project.

Question is am I considering the right materials for the job and what is the best way to join MDF panels together?

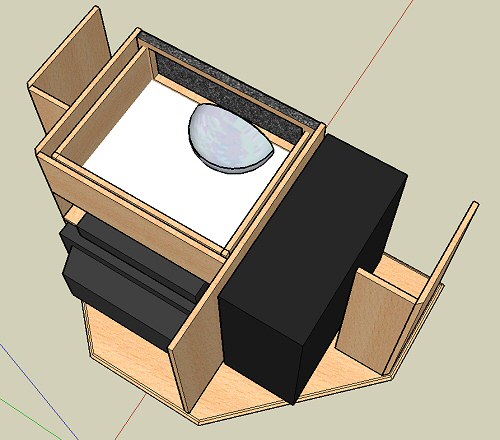

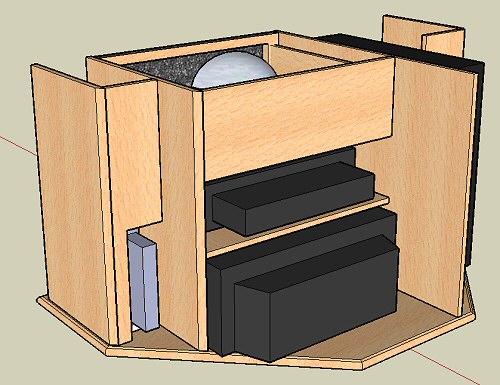

A few pictures of the design so far...

Have not bought the big screen yet. That will be the reward for finishing this project

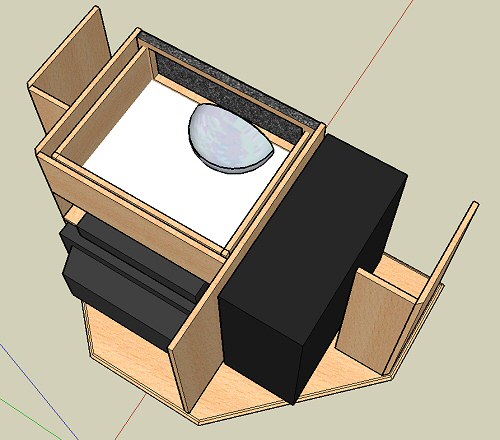

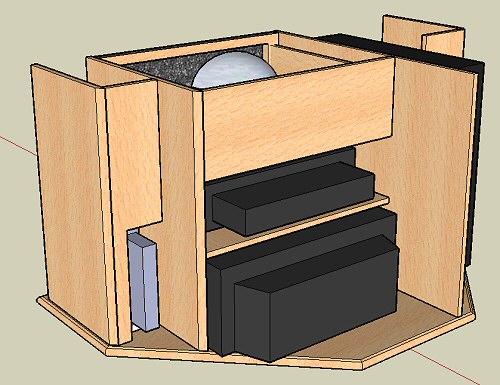

The big black box is a media centre computer

Front centre surround speaker is in a drawer (with cloth face) where other things like spare remote controls can be dropped in with it.

The funny blocks on the back of the amp etc is just allowing space for wires and plugs.

There will also be various holes in some panels to allow air flow and cable routes.

Oh and ignore the colour - I just used the beech texture from drawing my sideboard as it was easy!

Thanks in advance for any suggestions

I'm thinking of buying a sheet of 12mm oak veneered MDF to make most of it. Top and bottom I was thinking of gluing 6mm plain MDF to the undersides to make those 18mm thick. All the edges will be trimmed with oak and the top and bottom trims profiled to match small tables I made as my first ever project.

Question is am I considering the right materials for the job and what is the best way to join MDF panels together?

A few pictures of the design so far...

Have not bought the big screen yet. That will be the reward for finishing this project

The big black box is a media centre computer

Front centre surround speaker is in a drawer (with cloth face) where other things like spare remote controls can be dropped in with it.

The funny blocks on the back of the amp etc is just allowing space for wires and plugs.

There will also be various holes in some panels to allow air flow and cable routes.

Oh and ignore the colour - I just used the beech texture from drawing my sideboard as it was easy!

Thanks in advance for any suggestions