Rorton

Established Member

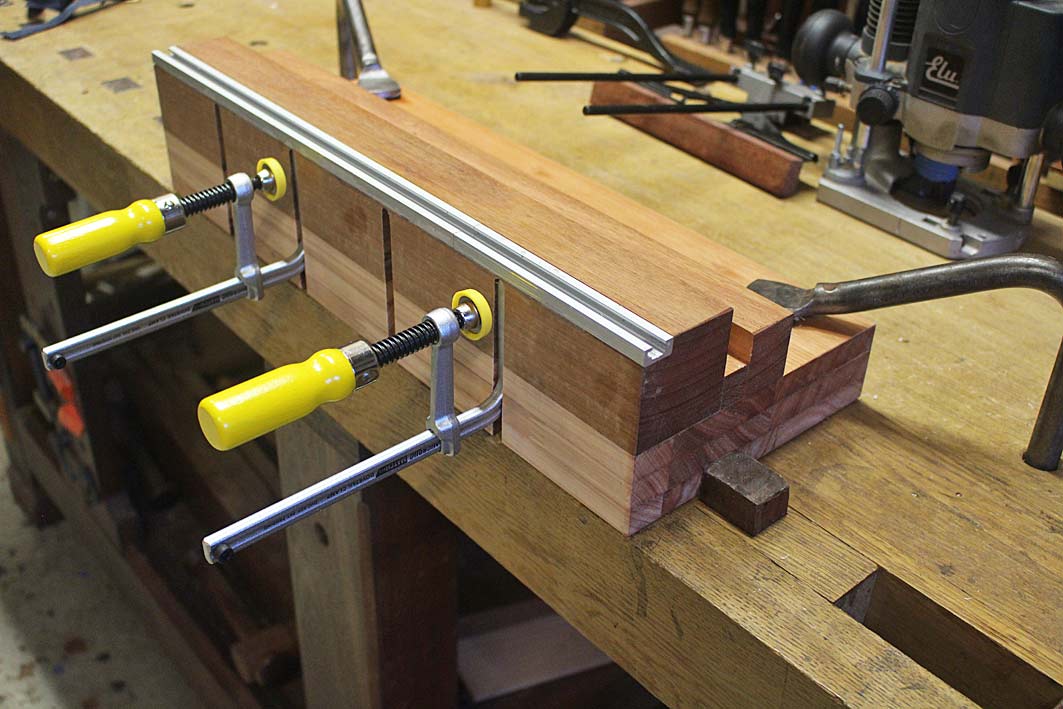

Been looking at the micro jig dovetail clamps, you route a dovetail slot in your timber, slide in the clamp to secure it, and instant clamping.

they seem expensive though, £50 for 2 clamps, so got me wondering about the normal f type clamps that are used to secure track saw track, could they be used, perhaps cut a t slot in the timber instead?

any one use them ?

they seem expensive though, £50 for 2 clamps, so got me wondering about the normal f type clamps that are used to secure track saw track, could they be used, perhaps cut a t slot in the timber instead?

any one use them ?