You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making your own Dominos

- Thread starter Chems

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Philly

Established Member

Gah! Thought you meant pizza.......

Philly :wink:

Philly :wink:

OPJ

Established Member

Good idea. Now all we need is a way to cut the slots without buying the tool!! :twisted: :wink:

If getting the round-over right is tricky, what about just cutting a chamfer, or even make the dominoes 1mm under width? It's unlike to affect the strength of the joint (biscuit slots tend to have loads of room to play) and they're bound to swell a bit once the glue goes on, anyway.

If getting the round-over right is tricky, what about just cutting a chamfer, or even make the dominoes 1mm under width? It's unlike to affect the strength of the joint (biscuit slots tend to have loads of room to play) and they're bound to swell a bit once the glue goes on, anyway.

Chems

Established Member

Its not tricky really, just a case of eyeballing it. Took all of a minute. It doesn't have to be great as if you leave it slightly large you can like you say just chamfer it down with a block plane with it clamped in the vice moving the domino over the base, or sand it down.

Mike.C

Established Member

Hi James, nice one. I am sure that if members knew that they could make a reliable domino for a fraction of the price, the cost of the machine would not seem so bad, because future expenses are down to a minimum.

What is the best/cheapest/reliable sort of timber to use for the Domino's

Cheers

Mike

What is the best/cheapest/reliable sort of timber to use for the Domino's

Cheers

Mike

Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 74

I'd have thought Steve M's dowel cutting jig for the bandsaw would be a deal quicker and safer than cutting them with the TS. Once you've made one up for domino biscuits, there's near-zero setup time and it would be really fast to produce loads from domino-profiled stock such as you ran up.

Assuming you can make, say, 100 at a time, how much cheaper would you say it is that than buying the Festool dowels? I can see one might get through them fairly fast

Assuming you can make, say, 100 at a time, how much cheaper would you say it is that than buying the Festool dowels? I can see one might get through them fairly fast

Chems

Established Member

I wouldn't ever make my own dominos except for a contrasting timber. The whole point of the domino is to be quick. It won't be if I have to make my own dominos!

Eric, I can only take it your not a big table saw user, what is un-safe about doing this? People need to get over the fright of a table saw, they are a brilliant machine, they can nip a finger off just as quick as the bandsaw. I haven't seen SteveMs jig, whats it like?

Eric, I can only take it your not a big table saw user, what is un-safe about doing this? People need to get over the fright of a table saw, they are a brilliant machine, they can nip a finger off just as quick as the bandsaw. I haven't seen SteveMs jig, whats it like?

Chems":97tpkls4 said:I wouldn't ever make my own dominos except for a contrasting timber.

Oh, is the contrasting timber what you use to put the spots on them ? :lol:

OPJ":97tpkls4 said:Good idea. Now all we need is a way to cut the slots without buying the tool!! :twisted: :wink:

Wouldn't it be just as easy to create a jig with 3 side by side holes and use dowels?

Chems

Established Member

OPJ":1zqbkxzb said:Good idea. Now all we need is a way to cut the slots without buying the tool!! :twisted: :wink:

Wouldn't it be just as easy to create a jig with 3 side by side holes and use dowels?[/quote]

That's already on the market. I don't remember what its called but the domino type things look like 3 dowels edge glued together.

Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 74

Chems":1bndbkpj said:I wouldn't ever make my own dominos except for a contrasting timber. The whole point of the domino is to be quick. It won't be if I have to make my own dominos!

Eric, I can only take it your not a big table saw user, what is un-safe about doing this? People need to get over the fright of a table saw, they are a brilliant machine, they can nip a finger off just as quick as the bandsaw. I haven't seen SteveMs jig, whats it like?

It's interesting that you picked up on "and safer"! No, I don't like using tablesaws much, it's true, but gradpa used to own a few Wadkin 24" (and bigger), and I used to play under them* as a child so I'm not really frightened of them.

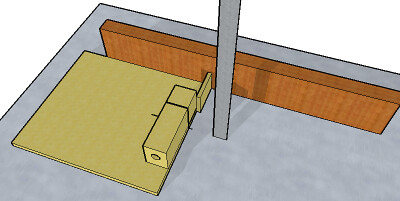

Steve's jig is on his bandsaw DVD, for mass-producing dowels quickly to length. It's incredibly simple:

Don't blame Steve: it's my drawing - blade guides, guards and blood soaked fingers omitted for clarity! A block of wood with a long hole through it mounted on a scrap of MDF. I guess you could put a bucket under the edge of the table to catch them coming off

Cheers,

*In the sawdust pits, when the mill was closed at the week-ends. I used to get into serious trouble, but sawdust fights are compelling when you're eight!

Chems

Established Member

Ah yes, great minds. I tried to set something up like that, if you look at my picture, the aux fence has a domino hole in the end. The trouble was that unlike a drill, the dominos make depth is 28mm and the 5mm dominos are 30mm dominos long. I could have cut in from the other end to achieve 56mm but decided just to use the crosscut.

Re the table saw, seems to be often when ever I post up me using the table saw someone says, you could have done that safer xyz. Its as if one shouldn't use the table saw at all! So that wasn't aimed at you as such sorry if it came off that way.

Re the table saw, seems to be often when ever I post up me using the table saw someone says, you could have done that safer xyz. Its as if one shouldn't use the table saw at all! So that wasn't aimed at you as such sorry if it came off that way.

OPJ

Established Member

I was thinking along the same lines as Eric; using Steve's bandsaw jig to crosscut them, rather than a table saw. Simply because I find tasks like this quite repetitive on a table saw - especially when you're using the large fence of a sliding table to cut such tiny little things (also, the kerf thickness means less waste with a bandsaw!  ).

).

You could probably make a similar jig for your table saw though, unless you're left-handed, you may want to move the rip fence to the left of the blade? If you have a mitre gauge, you could simply add a false fence to that (or, is that what you are doing in the photo...? :wink

:wink .

.

Obviously, a false fence providing clearance beside the saw blade is essential with whichever method you use.

If I was a Domino owner, I'm not sure I'd bother to make my own for regular use, either. I think the starter pack (systainer) is only about £160 and that includes all the cutters (which you don't get with the basic tool). Again, it's the initial outlay on the jointer that puts (most!) hobbyists off.

I did notice in the new Toolstation catalogue yesterday that the Freud (?) dowel jointer is coming down in price...

You could probably make a similar jig for your table saw though, unless you're left-handed, you may want to move the rip fence to the left of the blade? If you have a mitre gauge, you could simply add a false fence to that (or, is that what you are doing in the photo...?

Obviously, a false fence providing clearance beside the saw blade is essential with whichever method you use.

If I was a Domino owner, I'm not sure I'd bother to make my own for regular use, either. I think the starter pack (systainer) is only about £160 and that includes all the cutters (which you don't get with the basic tool). Again, it's the initial outlay on the jointer that puts (most!) hobbyists off.

I did notice in the new Toolstation catalogue yesterday that the Freud (?) dowel jointer is coming down in price...

Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 74

Chems":1jk1yfuu said:Ah yes, great minds. I tried to set something up like that, if you look at my picture, the aux fence has a domino hole in the end. The trouble was that unlike a drill, the dominos make depth is 28mm and the 5mm dominos are 30mm dominos long. I could have cut in from the other end to achieve 56mm but decided just to use the crosscut.

Re the table saw, seems to be often when ever I post up me using the table saw someone says, you could have done that safer xyz. Its as if one shouldn't use the table saw at all! So that wasn't aimed at you as such sorry if it came off that way.

Nah, I do understand!

With that jig, I liked the way the dowels are well away from the blade after they've been cut. The trouble with a TS for this job is you have to expose far more blade than you need, which is a bit of a nuisance.

Chems

Established Member

And I had to take the guard off to get pictures!

I've actually sent that guy who hurt his back a PM about that little bandsaw cause I'd really like to do a bit of veneer for my next job so maybe next time it comes to cutting them I can use that jig.

I bought the domino in stages, I got the machine for £425 (from America), I bought the small piece holder from Axy for £30 just after that. Someone else bought me the cross stop wings. I then bought the £160 systainer so I got the full kit for £615 which isn't half bad seen as just the base unit goes for £611 at Axy.

I've actually sent that guy who hurt his back a PM about that little bandsaw cause I'd really like to do a bit of veneer for my next job so maybe next time it comes to cutting them I can use that jig.

I bought the domino in stages, I got the machine for £425 (from America), I bought the small piece holder from Axy for £30 just after that. Someone else bought me the cross stop wings. I then bought the £160 systainer so I got the full kit for £615 which isn't half bad seen as just the base unit goes for £611 at Axy.

Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 74

Chems":2zi0zmle said:And I had to take the guard off to get pictures!

I've actually sent that guy who hurt his back a PM about that little bandsaw cause I'd really like to do a bit of veneer for my next job so maybe next time it comes to cutting them I can use that jig.

I bought the domino in stages, I got the machine for £425 (from America), I bought the small piece holder from Axy for £30 just after that. Someone else bought me the cross stop wings. I then bought the £160 systainer so I got the full kit for £615 which isn't half bad seen as just the base unit goes for £611 at Axy.

It's really annoying: manufacturers' prices here are too often 'because we can'. I posted a US price for a Bosch router elsewhere that's almost 50% of the UK price after you convert it. We shouldn't put up with it, but it's hard to see how things will change presently.

I have some sympathy for the distributors, as overheads here are far higher than in the USA, but that doesn't explain why some model's prices are within pennies of each other, no matter who you buy from.

Remind me: how many decades ago was resale price maintenance made illegal here?

I'd love a Domino - it's a well thought out bit of kit and obviously works very nicely, but there are too many other demands on my wallet!

Chems

Established Member

Eric The Viking":3nqs0dg5 said:I posted a US price for a Bosch router elsewhere that's almost 50% of the UK price after you convert it.

Is that the Bosch Colt, cause I saw one on the shelf in lowes, £75 it was. I was so tempted. But my suitcase already had one sustainer in it!

Mike H

Established Member

I have also made dominoes, but for a different purpose.

I find that the dominoes, in particular the large deep ones, are a devil for testing the fit. Often one has to pull them out with a mole wrench! The little ridge on the side is fine for the final glue up but can be a pain when the work needs a lot of pre assembly and testing.

I have made for most sizes reduced width dominoes for that purpose. I have not bothered with the rounding for some of those, some are left square others just double bevelled . It is cheap with offcuts and I store them with the rest.

They also come in handy when, say, one positioning exact one is needed, but the others can allow side movement, for example in a cleat/breadboard glued up with D1 glue for allowing creep.

I also wish that somebody sold decorative ones without glue channels, say in black walnut and maple for a start, so they can be left showing on some work..

Table saws: To cross cut lots of very small pieces off safely, when the accuracy of the table saw is needed, I have always used a very fine long wood wedge with a magnet so it sticks to the table. It can be positioned actually touching the blade face at its waxed tip and importantly needs to be set back to the width being cut plus a mil or two. When making squares for a batch of small chess boards last year I cut 100 at a time and they were just left there, the wedge makes sure they assemble in a bunch well away from the back teeth. My Grandpa showed me that trick in 1961.

I see that Felder market such a device now.

Cheers

Mike

8)

I find that the dominoes, in particular the large deep ones, are a devil for testing the fit. Often one has to pull them out with a mole wrench! The little ridge on the side is fine for the final glue up but can be a pain when the work needs a lot of pre assembly and testing.

I have made for most sizes reduced width dominoes for that purpose. I have not bothered with the rounding for some of those, some are left square others just double bevelled . It is cheap with offcuts and I store them with the rest.

They also come in handy when, say, one positioning exact one is needed, but the others can allow side movement, for example in a cleat/breadboard glued up with D1 glue for allowing creep.

I also wish that somebody sold decorative ones without glue channels, say in black walnut and maple for a start, so they can be left showing on some work..

Table saws: To cross cut lots of very small pieces off safely, when the accuracy of the table saw is needed, I have always used a very fine long wood wedge with a magnet so it sticks to the table. It can be positioned actually touching the blade face at its waxed tip and importantly needs to be set back to the width being cut plus a mil or two. When making squares for a batch of small chess boards last year I cut 100 at a time and they were just left there, the wedge makes sure they assemble in a bunch well away from the back teeth. My Grandpa showed me that trick in 1961.

I see that Felder market such a device now.

Cheers

Mike

8)

Chems

Established Member

That's the one!

Mike, yeah I know what you mean. That smaller domino idea for dry fit is a great idea.

Mike, yeah I know what you mean. That smaller domino idea for dry fit is a great idea.

Benchwayze

Established Member

I think if I made my own domino biscuits, I would choose exterior grade ply of the right thickness. (Natch!)

That's what I use for slip tenons which, as I don't square off mortice ends, look like 'giant' dominos!

:wink:

Chems,

You home-made idea would work well if you did a 'Krenov' on the supports, and shaped them, as a design feature.

John

That's what I use for slip tenons which, as I don't square off mortice ends, look like 'giant' dominos!

:wink:

Chems,

You home-made idea would work well if you did a 'Krenov' on the supports, and shaped them, as a design feature.

John