DavidE

Established Member

I am currently looking at building some Oak stairs with/for a friend. The setup is quite straightforward two runs about 7ft long with 7 or so treads. I would like to cut housings into the stringers. I have a couple of books notably Carpentry and Joinery by Peter Brett and Taunton’s Building Stairs. These contain some good tips and techniques. I am quite happy with the general method of cutting tapered slots and knocking wedges in…

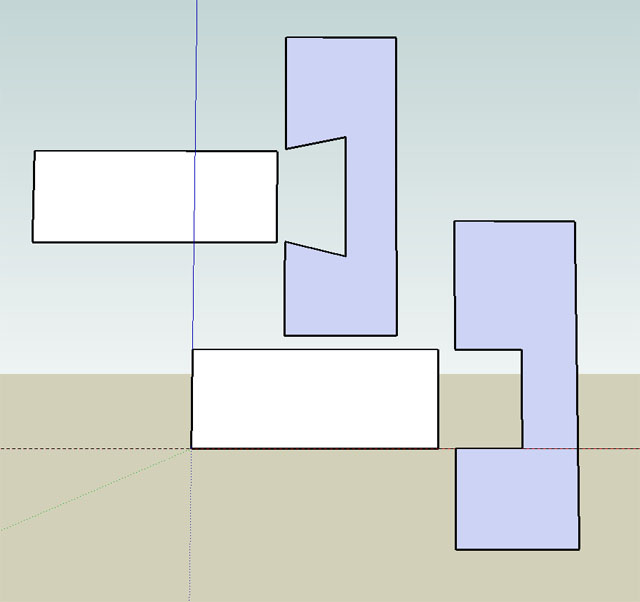

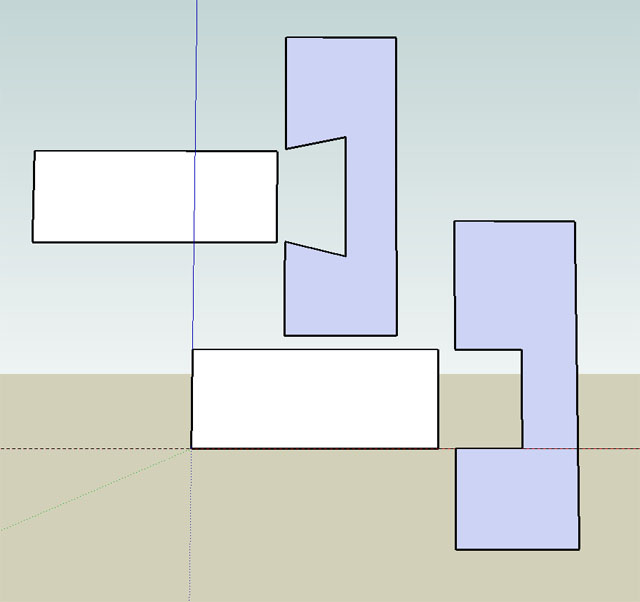

One thing neither book mentions though I’ve seen it once on here and also seen the router cutters is the practice of dovetailing the housing, as opposed to a straight joint. The drawing shows my understanding of how this works (no wedges shown).

I’m confused though – I can see the dovetail has the potential for a tight joint as when the wedges are knocked in the wood will compress and almost dig into the tread. However, I wonder if this runs the risk of damaging the wood fibres along the sharp edge? Also, depending how much it compresses – you’re only making use of the part depth of the housing.

Am I just being paranoid here or are there any other tricks to remember when doing this?

Also I am wondering about open plan stairs for the top level. I have been looking for some wisdom on this. Part of me thinks a full housing would be okay – then I worry about expansion. If I tenon the ends slightly this runs the risk of showing gaps, I have thought about half housings as well though they all seem to have the same problem. One design I have seen shows wedged through tenons I’d rather not have anything showing on the outside of the stringer though. Are there any top tips for this?

Thanks, David

One thing neither book mentions though I’ve seen it once on here and also seen the router cutters is the practice of dovetailing the housing, as opposed to a straight joint. The drawing shows my understanding of how this works (no wedges shown).

I’m confused though – I can see the dovetail has the potential for a tight joint as when the wedges are knocked in the wood will compress and almost dig into the tread. However, I wonder if this runs the risk of damaging the wood fibres along the sharp edge? Also, depending how much it compresses – you’re only making use of the part depth of the housing.

Am I just being paranoid here or are there any other tricks to remember when doing this?

Also I am wondering about open plan stairs for the top level. I have been looking for some wisdom on this. Part of me thinks a full housing would be okay – then I worry about expansion. If I tenon the ends slightly this runs the risk of showing gaps, I have thought about half housings as well though they all seem to have the same problem. One design I have seen shows wedged through tenons I’d rather not have anything showing on the outside of the stringer though. Are there any top tips for this?

Thanks, David