Dalboy

Established Member

Things I have learnt from entering the competition.

First and foremost read the Bl---y rules properly

Next I managed to learn how to use my spiralling tool (not perfectly but acceptable enough)

So this is a good thing for people to enter well the second one at least in as much that it can teach you new skills (In my case maybe) :lol:

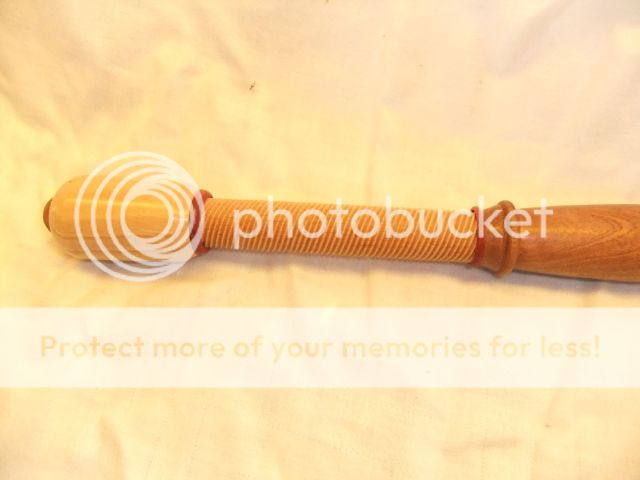

Any way I said I would post my fisherman's priest which would have been disqualified.

1 for texturing

2 using colour

and 3 not from 1 piece of wood.

All my own fault

First and foremost read the Bl---y rules properly

Next I managed to learn how to use my spiralling tool (not perfectly but acceptable enough)

So this is a good thing for people to enter well the second one at least in as much that it can teach you new skills (In my case maybe) :lol:

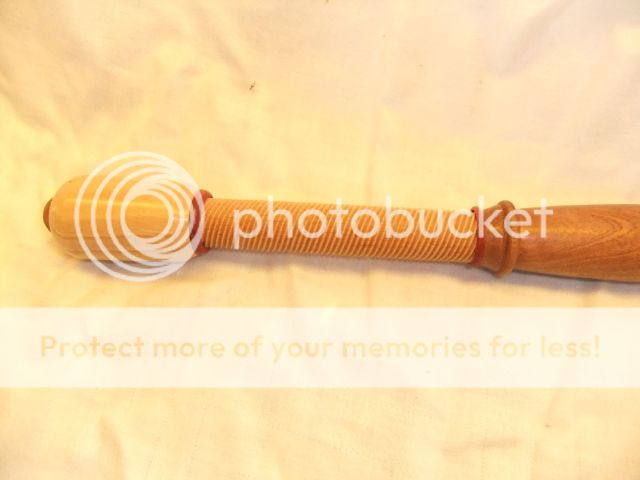

Any way I said I would post my fisherman's priest which would have been disqualified.

1 for texturing

2 using colour

and 3 not from 1 piece of wood.

All my own fault