dedee

Established Member

What is is the best method of cutting thin stainless steel sheet?

I need to cut a piece of 0.6mm stainless steel sheet. The cut will be 65cm long so a hacksaw is out of the question.

I have an angle grinder but was wondering if it would be better to glue the steel to a piece of mdf/hardboard/ply before cutting.

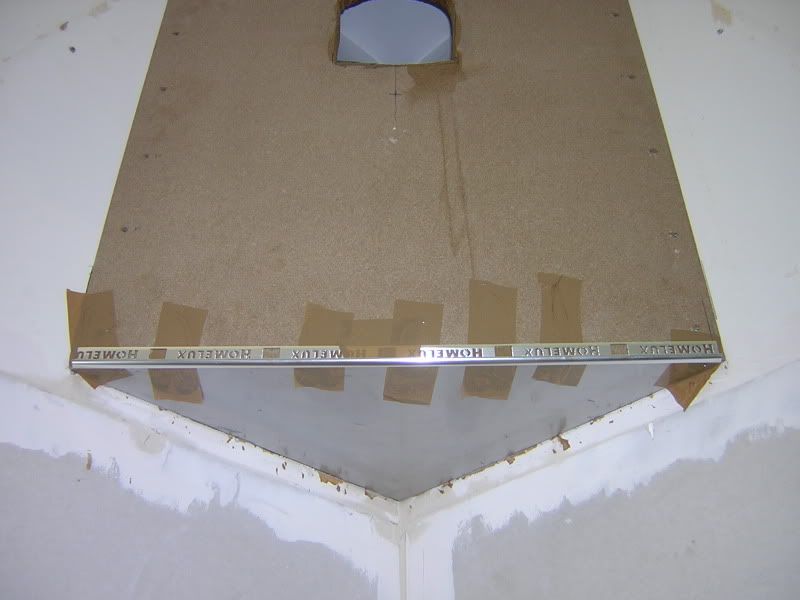

The cut piece will be mounted to a horizontal surface in the kitchen behind and above the hob which is set into the corner of a worktop.

Andy

I need to cut a piece of 0.6mm stainless steel sheet. The cut will be 65cm long so a hacksaw is out of the question.

I have an angle grinder but was wondering if it would be better to glue the steel to a piece of mdf/hardboard/ply before cutting.

The cut piece will be mounted to a horizontal surface in the kitchen behind and above the hob which is set into the corner of a worktop.

Andy