Mcluma

Established Member

How do you turn a positive outline into a negative?

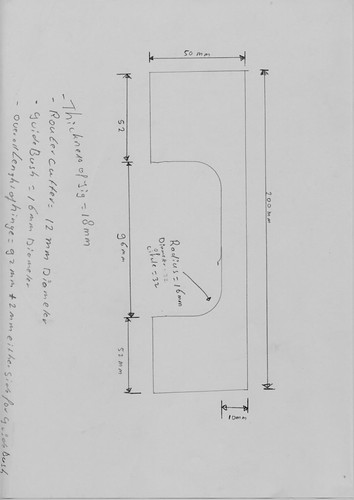

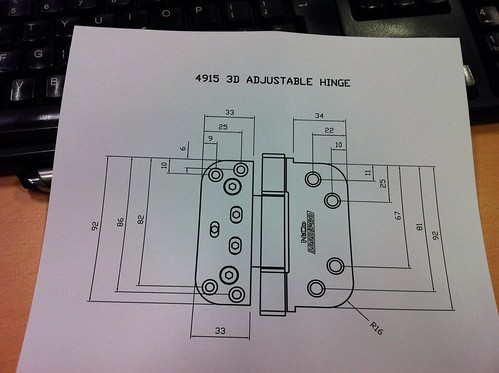

I have been cutting these hinges with the router following a template. These templates were made by me using the band saw, following a pencil line – the template is good, but not perfect – I am looking for something better

I spoke to Trend the manufacturer of the hinge jig but they do not have anything in there program to actually match a 16 degree corner – it can be done by using a 32mm cutter – well these are not available – so the best option is to have a template

Is there a way by actually using the hinge itself and a router to create from the hinge outline a template?

I can then use the guide bush to ride up against the template and make the hinge cut out.

Untitled by mcluma, on Flickr

I have been cutting these hinges with the router following a template. These templates were made by me using the band saw, following a pencil line – the template is good, but not perfect – I am looking for something better

I spoke to Trend the manufacturer of the hinge jig but they do not have anything in there program to actually match a 16 degree corner – it can be done by using a 32mm cutter – well these are not available – so the best option is to have a template

Is there a way by actually using the hinge itself and a router to create from the hinge outline a template?

I can then use the guide bush to ride up against the template and make the hinge cut out.

Untitled by mcluma, on Flickr