MrDavidRoberts

Established Member

- Joined

- 23 Dec 2016

- Messages

- 388

- Reaction score

- 2

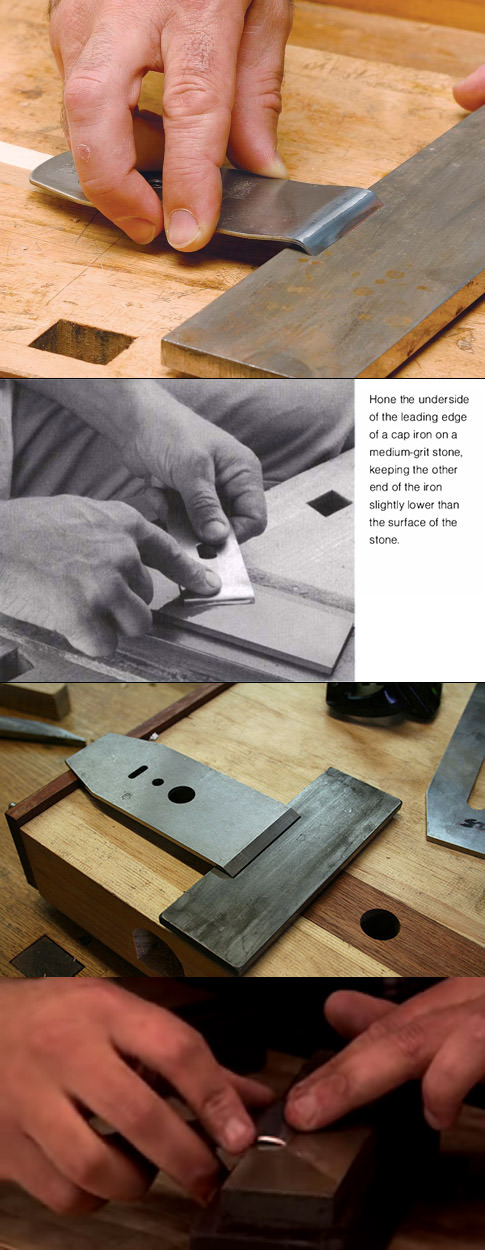

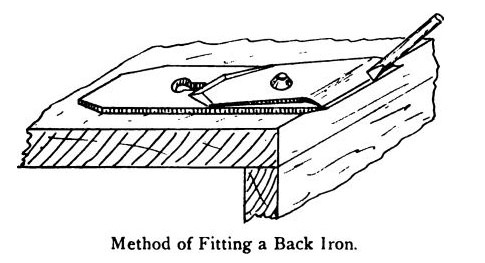

I'm still struggling with this.. I just have no idea how to actually sharpen the chipbreaker so it doesn't catches any shavings/dust under it..

There are Tons of videos about how to ''set'' the chipbreaker and telling what it should be like( straight/no light coming etc...) but there is not a single guide that I can find on how do you actually sharpen it to be like that?

At what angle do you even sharpen it? how do you do it exactly? How do you hold it when sharpening it etc? Do you need to remove any burr etc? There is no way you can do it by just holding it freehand and trying to match the original angle as you can't really see the exact angle, even the slightest fault in the angle will create a gap which will let the chips in.

There are Tons of videos about how to ''set'' the chipbreaker and telling what it should be like( straight/no light coming etc...) but there is not a single guide that I can find on how do you actually sharpen it to be like that?

At what angle do you even sharpen it? how do you do it exactly? How do you hold it when sharpening it etc? Do you need to remove any burr etc? There is no way you can do it by just holding it freehand and trying to match the original angle as you can't really see the exact angle, even the slightest fault in the angle will create a gap which will let the chips in.