Benchwayze

Established Member

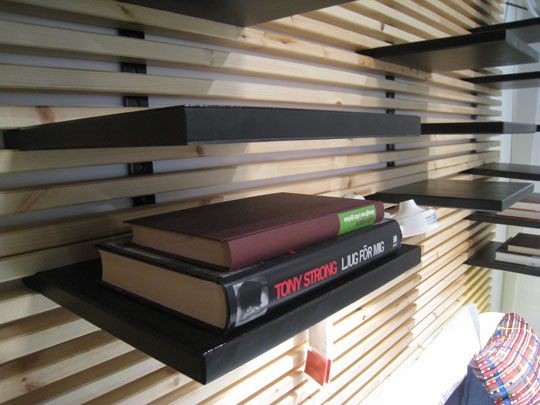

Somewhere on t'interweb I saw a piece on a 'slatted tool-wall', fixed above a workbench.

As far as I could tell, the foundation consisted of upright wall mounted studs. Fixed to the studs were half a dozen or so horizontal slats, about 3 x 1 inches each, and spaced approx 3/4" apart; (depending on the thickness of shelving material.) No mention was made of any support proved above the concealed, rear edges of the shelving to prevent tipping. It was claimed the shelves would just slide in between the slats, and would stay cantilevered, with both planes level, and would hold weight without tipping forwards. .

I am having difficulty in grasping this, and I can't see how you can dispense with support above the rear edges of the shelf,

Can anyone who has tried this enlighten me how this works without support above the rear edges? Or am I just missing something? Perhaps the horizontal slats need to be a certain distance from the wall behind?

Thanks in anticipation.

.

As far as I could tell, the foundation consisted of upright wall mounted studs. Fixed to the studs were half a dozen or so horizontal slats, about 3 x 1 inches each, and spaced approx 3/4" apart; (depending on the thickness of shelving material.) No mention was made of any support proved above the concealed, rear edges of the shelving to prevent tipping. It was claimed the shelves would just slide in between the slats, and would stay cantilevered, with both planes level, and would hold weight without tipping forwards. .

I am having difficulty in grasping this, and I can't see how you can dispense with support above the rear edges of the shelf,

Can anyone who has tried this enlighten me how this works without support above the rear edges? Or am I just missing something? Perhaps the horizontal slats need to be a certain distance from the wall behind?

Thanks in anticipation.

.