swagman

Established Member

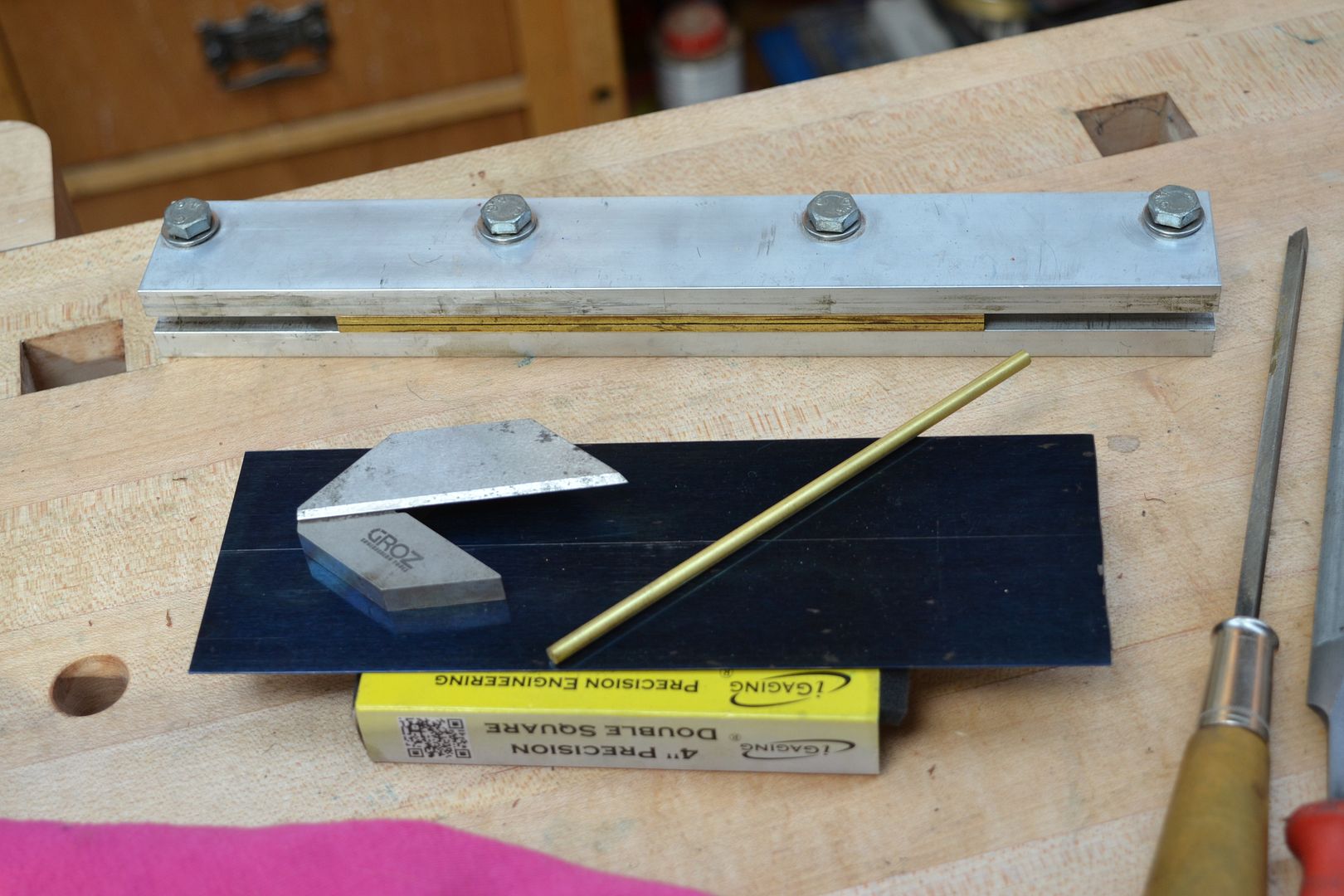

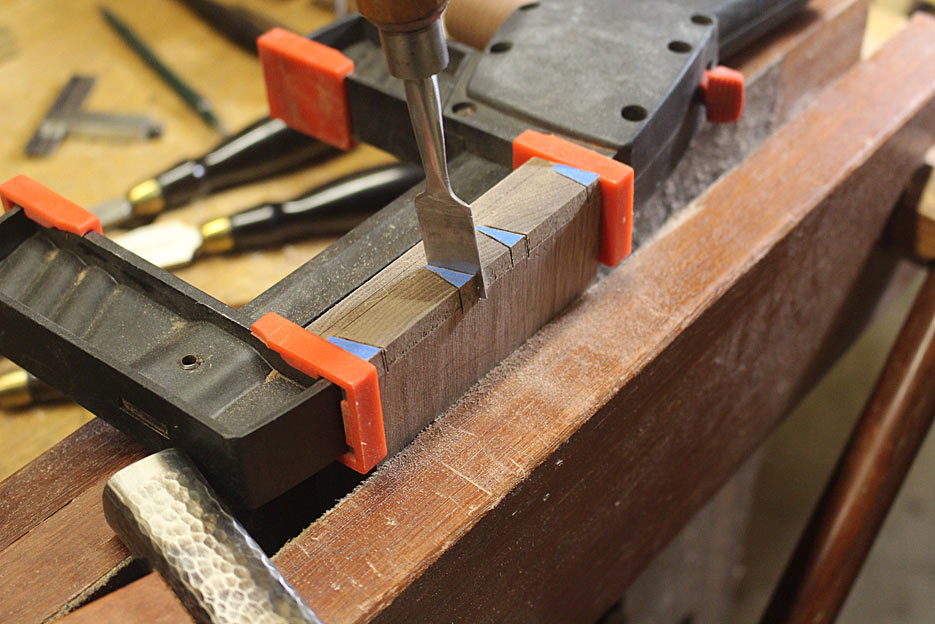

The tool is designed for deepening the kerf depth on half blind dovetails. For those not familiar with its use watch the following video from 1.00min by Rob Cosman. https://www.youtube.com/watch?v=XY9MzSCvxc8

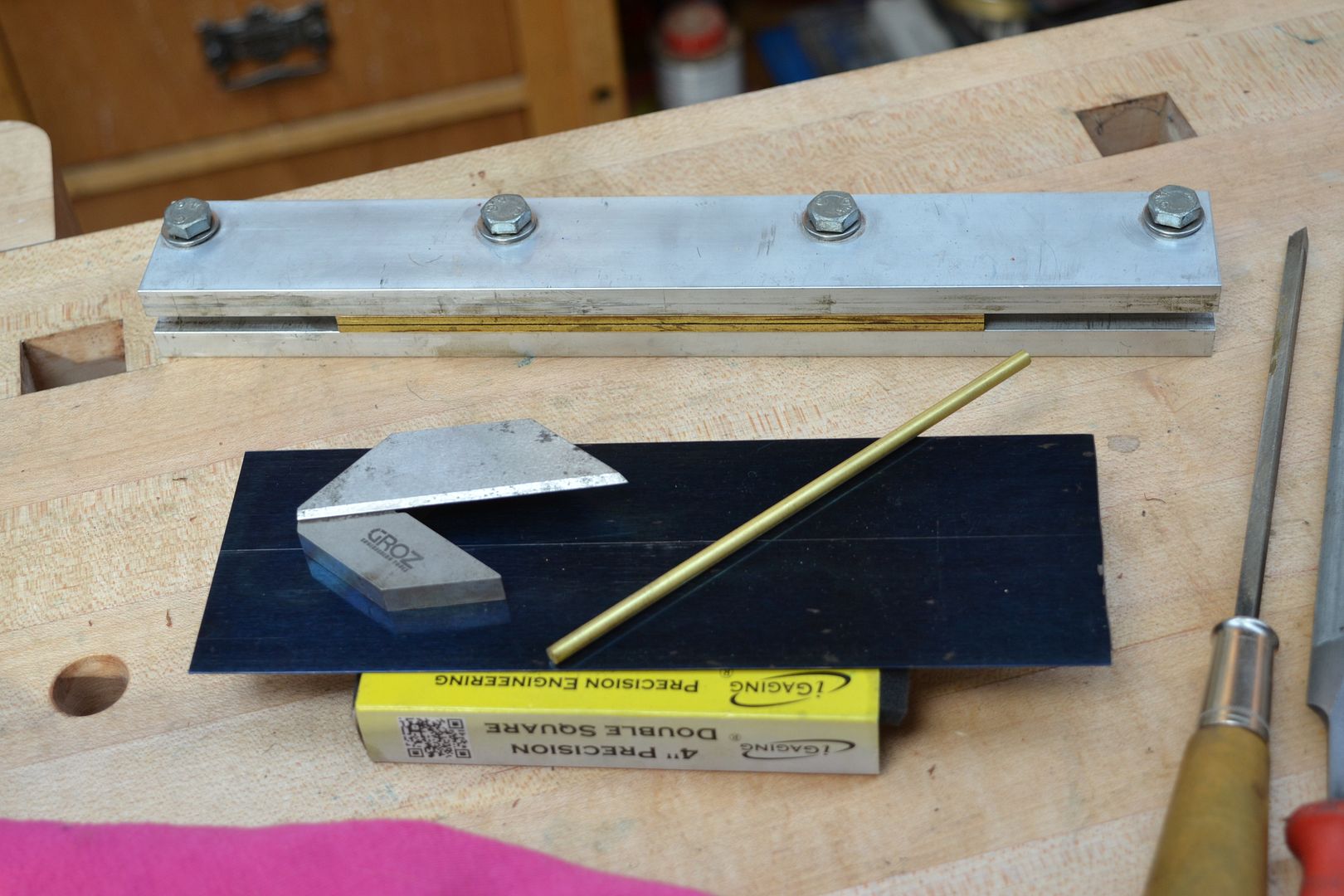

The design I made features an 0.025" saw plate gauge x 3 1/2" (length) x 1 1/4" (depth below spine). The 3/16" brass pins used to secure the saw plate, and handle fit, were 1st 2 part epoxied, then hammer peened to achieve a lock tight fit.

The pins used through the saw plate feature a pierced pattern commonly used by knife makers.

The brass parts received a final sanding to 1200 grit.

Lock-tite was used to secure the saw plate within the brass spine slot prior to pinning.

Time taken to complete this project was around 6hrs. (excludes handle).

Stewie;

The design I made features an 0.025" saw plate gauge x 3 1/2" (length) x 1 1/4" (depth below spine). The 3/16" brass pins used to secure the saw plate, and handle fit, were 1st 2 part epoxied, then hammer peened to achieve a lock tight fit.

The pins used through the saw plate feature a pierced pattern commonly used by knife makers.

The brass parts received a final sanding to 1200 grit.

Lock-tite was used to secure the saw plate within the brass spine slot prior to pinning.

Time taken to complete this project was around 6hrs. (excludes handle).

Stewie;