devonwoody

Established Member

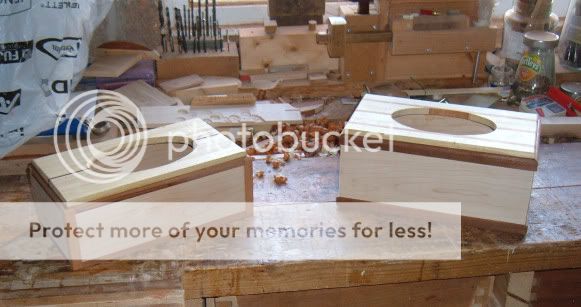

I am starting a new tissue box. :wink:

My eye has healed, although I might be laid up again in 14 days when stitches have been removed.

So I found this piece of Meranti from remains of our old window frames and because it is already rebated I am wanting to make it a feature.

Bits of maple also laying around but need beefing up a bit, they are under width, so more brown wood put on bench.

My eye has healed, although I might be laid up again in 14 days when stitches have been removed.

So I found this piece of Meranti from remains of our old window frames and because it is already rebated I am wanting to make it a feature.

Bits of maple also laying around but need beefing up a bit, they are under width, so more brown wood put on bench.