SPinonit

Established Member

Hi there, I've got a lot of inspiration from this forum and decided to build a workbench. I'm sure I read somewhere that building a workbench is a good starter project, but I guess it's almost essential to have one if you intend making much else.

Anyhow, I saw Lord Nibbo's masterpiece (I would love to build something like that eventually) and I also noticed Paul Champan's built using layered MDF for the worktop. I thought I'd try to combine a few ideas from both into mine. I used the general style and layout and took the three full size drawers and the tenons on the top of the legs to locate the worktop from LN's bench. I used the MDF worktop and the back buffer (stop) from Paul's - plus the apparent simplicity, which gave me the confidence to have a go.

A bit of background about me before I go too much further might stave off some rather harsh criticisms of my 'masterpiece'. I haven't done any woordworking since around 1980, when I was told by my secondary school that I could not do 'O' level woodworking as they needed the space to allow girls in that class for the first time. I was offered metalworking, home economics or some sort of typing class. The last two wanted to attract boys since lots of girls had abandoned these classes to take my space in woodwork! lol

Since then, I've done ad-hoc diy stuff, but until now, nothing you can call proper woodworking. Arguably, whatever I'm doing now may still not be proper woodworking, although my last bit of background might in part explain why. Followng a bad motorcycle accident with a mysterious hit and run driver, I lost the use of one arm - so I'm literally doing this single-handedly.

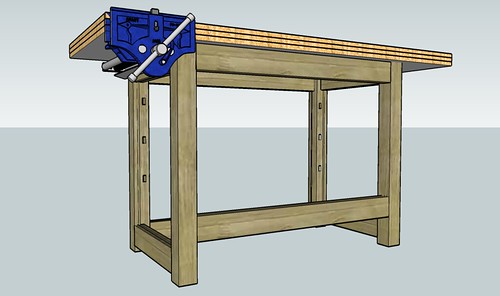

In addition, I have picked up most of my tools second-and from ebay or sale items. The wood I have used is also not the most ideal, but I have tried to recycle whatever I had lying around in the garage. Mostly, this consisted of exterior grade sawn landscaping timber - pressure treated for decking etc. It was a bit twisted in some cases and I've had to be rather creative with some of it. I used Sketchup to draw the plans before cutting any timber, so I was happy that it should all fit properly - so far I've been very luckly and it's gone together ok. So far, it's cost me about £7 in new materials (MDF) and has taken a couple of weeks to get this far.

So far, I have built the carcass and today, I was hoping to add the layered MDF worktop. I need to work out how to fit the vice - a Record 52 1/2 9". Originally, I had planned to fit it to the left of the workbench and just mount it under the worktop, however, it is a very heavy item and I'm concerned the weight might distort the top. Any advice or suggestions would be very gratefully received.

I have some pics (and I guess the Sketchup plan), which I would happily post, if I knew how. Not sure how to upload images onto the forum.

Thanks

Steve

Anyhow, I saw Lord Nibbo's masterpiece (I would love to build something like that eventually) and I also noticed Paul Champan's built using layered MDF for the worktop. I thought I'd try to combine a few ideas from both into mine. I used the general style and layout and took the three full size drawers and the tenons on the top of the legs to locate the worktop from LN's bench. I used the MDF worktop and the back buffer (stop) from Paul's - plus the apparent simplicity, which gave me the confidence to have a go.

A bit of background about me before I go too much further might stave off some rather harsh criticisms of my 'masterpiece'. I haven't done any woordworking since around 1980, when I was told by my secondary school that I could not do 'O' level woodworking as they needed the space to allow girls in that class for the first time. I was offered metalworking, home economics or some sort of typing class. The last two wanted to attract boys since lots of girls had abandoned these classes to take my space in woodwork! lol

Since then, I've done ad-hoc diy stuff, but until now, nothing you can call proper woodworking. Arguably, whatever I'm doing now may still not be proper woodworking, although my last bit of background might in part explain why. Followng a bad motorcycle accident with a mysterious hit and run driver, I lost the use of one arm - so I'm literally doing this single-handedly.

In addition, I have picked up most of my tools second-and from ebay or sale items. The wood I have used is also not the most ideal, but I have tried to recycle whatever I had lying around in the garage. Mostly, this consisted of exterior grade sawn landscaping timber - pressure treated for decking etc. It was a bit twisted in some cases and I've had to be rather creative with some of it. I used Sketchup to draw the plans before cutting any timber, so I was happy that it should all fit properly - so far I've been very luckly and it's gone together ok. So far, it's cost me about £7 in new materials (MDF) and has taken a couple of weeks to get this far.

So far, I have built the carcass and today, I was hoping to add the layered MDF worktop. I need to work out how to fit the vice - a Record 52 1/2 9". Originally, I had planned to fit it to the left of the workbench and just mount it under the worktop, however, it is a very heavy item and I'm concerned the weight might distort the top. Any advice or suggestions would be very gratefully received.

I have some pics (and I guess the Sketchup plan), which I would happily post, if I knew how. Not sure how to upload images onto the forum.

Thanks

Steve