memzey

Established Member

Hi,

I've taken the plunge on the slippery slope of old English hand tools and gone to my first boot sale this morning in the hope of picking up good old English users. Most of it came from house clearance sellers who were present in abundance. Please take a look and give me your thoughts:

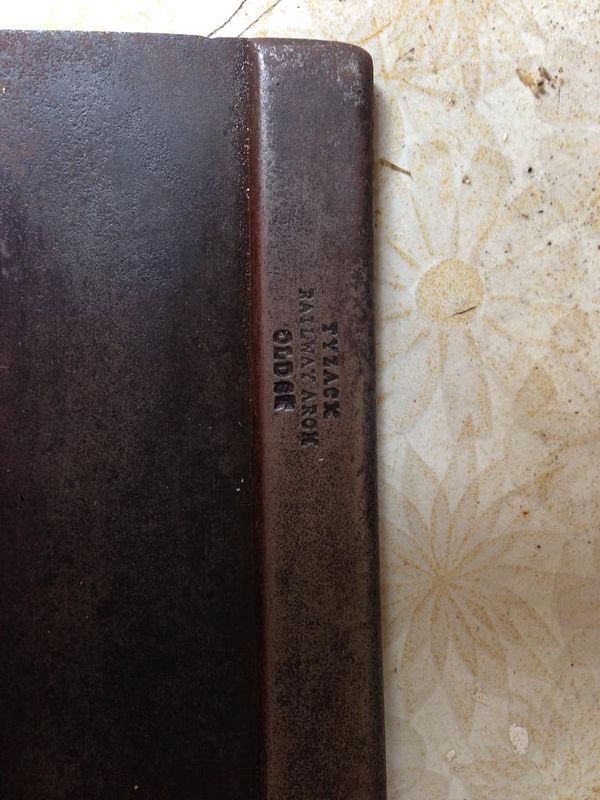

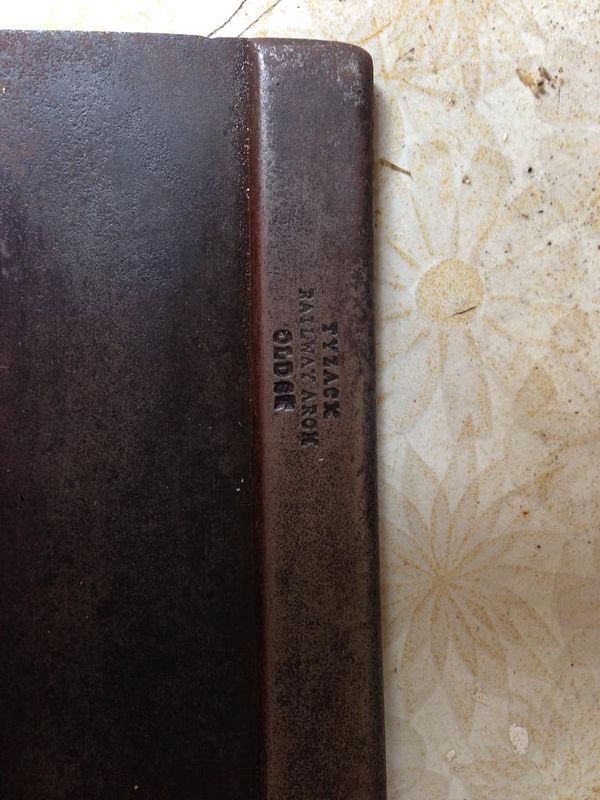

First up is an old dovetail saw:

It fits really well in the hand, is straight and cuts ok. I've read others mention this brand so hopefully it's a goody:

It does have a crack in the handle though which is a bit of a worry. Can this be fixed? Is it also possible to source split nuts to replace the ugly fix it has at present?

Next up a rather lovely hammer/mallet:

Leather on one side copper on the other. Beautiful.

Now we move on to the chisels:

All straight, with tidy handles and in fairly good nick. Also all made in England. From left to right we have the following:

This is a nice beefy one about 1"

Then one a little smaller:

A bit smaller:

And one smaller still:

This is an interesting one. I'm not famiar with the maker but think it's something Bell & Son - does anyone know?

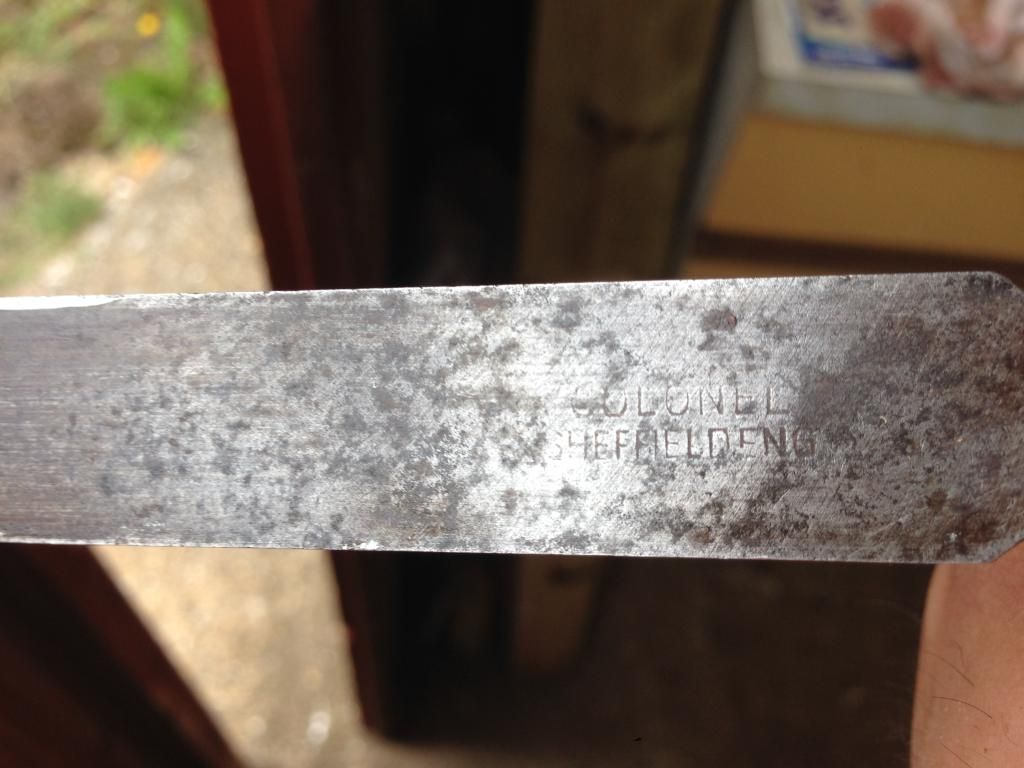

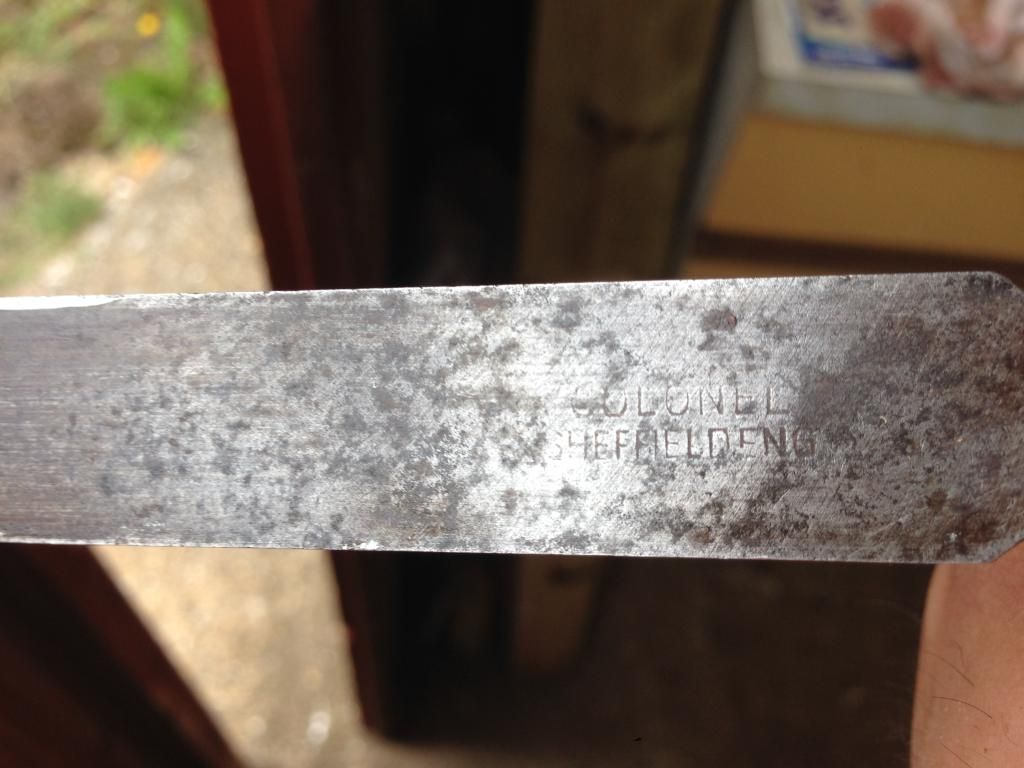

Then there is this one:

Does the maker ring any bells with anyone? It feels lovely and well made in the hand is all I can say at this stage.

There is another chisel of which I can't make out the mark:

Does anyone have any tips on cleaning these up and restoring them? Please assume you are giving instruction to a cack handed cretin.

Then we have the oil stones:

The South African Carbonundurum combi has never been used judging by the rate it is soaking up 3 in one at the moment. The smaller one in the wooden box feels very fine but has clearly had a hard life. Any hints on bringing it back to life?

Then some clamps. As Norm always says "you can never have too many clamps"

The G clamps are all Record made in England. I also got a tin of 3 in one thrown in.

So what do we think of this hall? Is there anything of note or interest amongst this lot? Everything was bought for 50p an item or less so I am fairly relaxed as regards to value but it would be good to know if people on this board think I've been ripped off or done quite well!

I've taken the plunge on the slippery slope of old English hand tools and gone to my first boot sale this morning in the hope of picking up good old English users. Most of it came from house clearance sellers who were present in abundance. Please take a look and give me your thoughts:

First up is an old dovetail saw:

It fits really well in the hand, is straight and cuts ok. I've read others mention this brand so hopefully it's a goody:

It does have a crack in the handle though which is a bit of a worry. Can this be fixed? Is it also possible to source split nuts to replace the ugly fix it has at present?

Next up a rather lovely hammer/mallet:

Leather on one side copper on the other. Beautiful.

Now we move on to the chisels:

All straight, with tidy handles and in fairly good nick. Also all made in England. From left to right we have the following:

This is a nice beefy one about 1"

Then one a little smaller:

A bit smaller:

And one smaller still:

This is an interesting one. I'm not famiar with the maker but think it's something Bell & Son - does anyone know?

Then there is this one:

Does the maker ring any bells with anyone? It feels lovely and well made in the hand is all I can say at this stage.

There is another chisel of which I can't make out the mark:

Does anyone have any tips on cleaning these up and restoring them? Please assume you are giving instruction to a cack handed cretin.

Then we have the oil stones:

The South African Carbonundurum combi has never been used judging by the rate it is soaking up 3 in one at the moment. The smaller one in the wooden box feels very fine but has clearly had a hard life. Any hints on bringing it back to life?

Then some clamps. As Norm always says "you can never have too many clamps"

The G clamps are all Record made in England. I also got a tin of 3 in one thrown in.

So what do we think of this hall? Is there anything of note or interest amongst this lot? Everything was bought for 50p an item or less so I am fairly relaxed as regards to value but it would be good to know if people on this board think I've been ripped off or done quite well!