Hi,

I'm new to the forum, yesterday actually, and have been pouring over the forums which are a treasure trove of advice and ideas! I'm recently 'retired' early so have plenty of time now to pursue my hobby interests, one of which is DIY woodworking.

I'm planning to make a new front door for my cottage and my material choice is oak or idigbo. I was originally going to buy one of those engineered wood versions till I realised that they come in standard sizes and they are no good if they are exposed to the rain!! :lol: So I'm going to have to make one.

The style of door I want is a cottage style with a small vision panel. I would like the door to be double boarded which means there won't be room for a mid-rail. What concerns me is the likelihood for the door to twist/move etc. To try to combat this I'm proposing to make the door frame as follows:

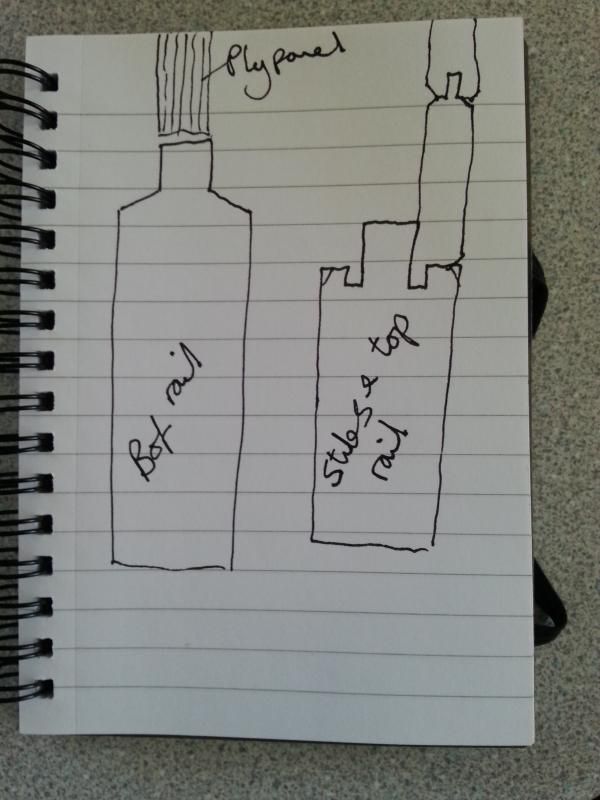

Stiles: 144x44, top rail: 125x44, bot. rail: 219x44. All joints through tenon. Panel to be 12mm ply sandwiched between 16mm oak/idigbo facing boards. I'm not sure of the best way of fixing the facing boards. I was figuring on gluing them to the ply with Cascamite, given that they are only 16mm thick. Or is it better to use 18mm ply with 13mm glued boards?

Below are 'typical sections' through the door, showing my proposed construction. The ply core would be edge sealed with slow cure epoxy to help prevent end grain moisture absorption and I'm proposing to overlap the facing boards at rail/stile junctions to reduce water ingress. Where the facing panel rebates meet the head of the vision panel I was proposing to 'plug' these with Sikaflex to prevent water holding behind the top of the vision panel frame.

What I'd like to ask, of those guys who know their stuff regarding door construction, is whether the proposed construction, whilst maybe a little unorthodox, should do the job. The materials aren't cheap and so I don't want to go to all the trouble of making the door only to find it's going to fail. If not can anyone suggest a better way to build the door?

I'm not a joiner so my apologies if my terminology isn't spot on. I've made a few woodwork projects before, including a pair of pitch pine louvre doors for a woodshed I built last year along with a pair of sapele gates (see photo below), so I'm hoping my experiences with these doors, gates and other projects will carry me through.

Thanks for taking the time to read this guys. I look forward to your thoughts.

I'm new to the forum, yesterday actually, and have been pouring over the forums which are a treasure trove of advice and ideas! I'm recently 'retired' early so have plenty of time now to pursue my hobby interests, one of which is DIY woodworking.

I'm planning to make a new front door for my cottage and my material choice is oak or idigbo. I was originally going to buy one of those engineered wood versions till I realised that they come in standard sizes and they are no good if they are exposed to the rain!! :lol: So I'm going to have to make one.

The style of door I want is a cottage style with a small vision panel. I would like the door to be double boarded which means there won't be room for a mid-rail. What concerns me is the likelihood for the door to twist/move etc. To try to combat this I'm proposing to make the door frame as follows:

Stiles: 144x44, top rail: 125x44, bot. rail: 219x44. All joints through tenon. Panel to be 12mm ply sandwiched between 16mm oak/idigbo facing boards. I'm not sure of the best way of fixing the facing boards. I was figuring on gluing them to the ply with Cascamite, given that they are only 16mm thick. Or is it better to use 18mm ply with 13mm glued boards?

Below are 'typical sections' through the door, showing my proposed construction. The ply core would be edge sealed with slow cure epoxy to help prevent end grain moisture absorption and I'm proposing to overlap the facing boards at rail/stile junctions to reduce water ingress. Where the facing panel rebates meet the head of the vision panel I was proposing to 'plug' these with Sikaflex to prevent water holding behind the top of the vision panel frame.

What I'd like to ask, of those guys who know their stuff regarding door construction, is whether the proposed construction, whilst maybe a little unorthodox, should do the job. The materials aren't cheap and so I don't want to go to all the trouble of making the door only to find it's going to fail. If not can anyone suggest a better way to build the door?

I'm not a joiner so my apologies if my terminology isn't spot on. I've made a few woodwork projects before, including a pair of pitch pine louvre doors for a woodshed I built last year along with a pair of sapele gates (see photo below), so I'm hoping my experiences with these doors, gates and other projects will carry me through.

Thanks for taking the time to read this guys. I look forward to your thoughts.