BradNaylor

Established Member

- Joined

- 17 Oct 2007

- Messages

- 2,311

- Reaction score

- 2

We've been busy this week making a pair of oak wardrobes for a regular client. 4 days in the workshop and a full day today for Phil and I assembling them. (Karl was having a very well deserved day off!)

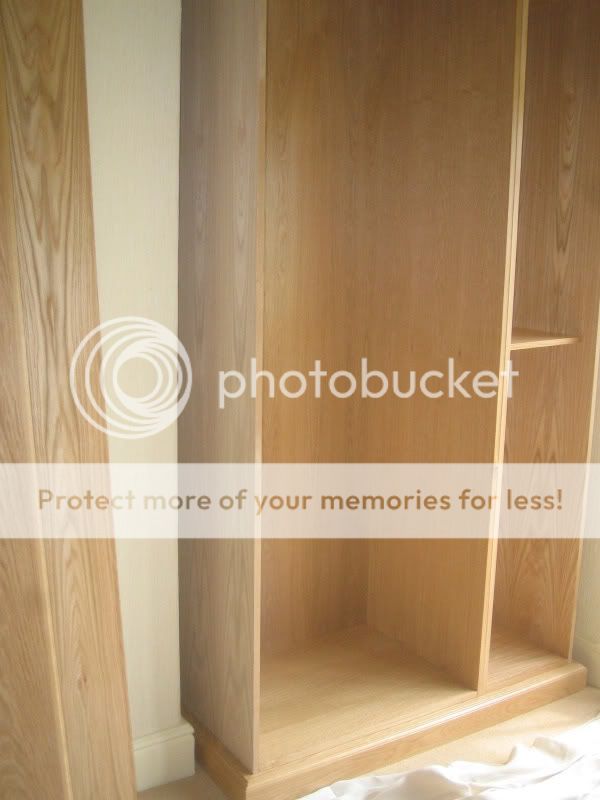

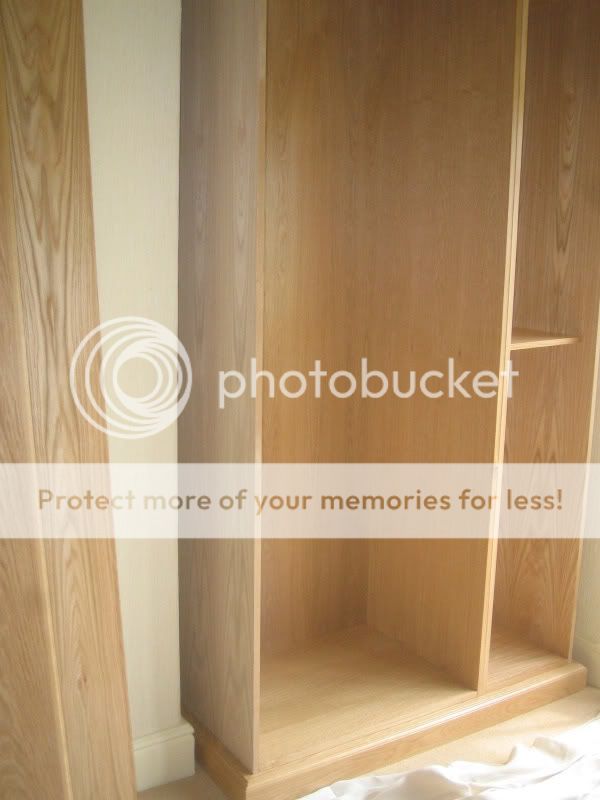

First in is the plinth on adjustable feet for levelling.

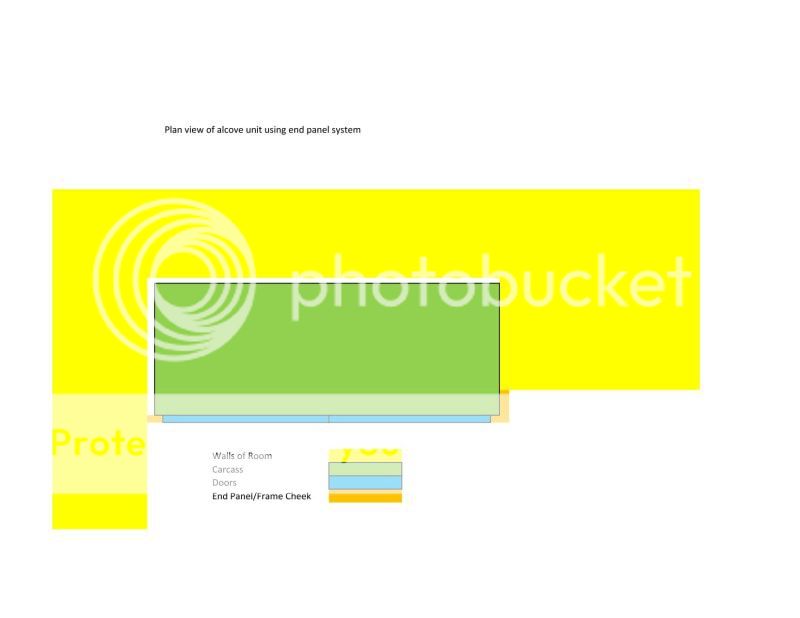

The carcasses are simply boxes of veneered MDF

The end panels with wrap-round face frames are then attached

The cornice is ready made in the workshop and slid into position

The doors are fitted with concealed hinges and we're finished

The customer was delighted and and confirmed that they want us to build them a new bling kitchen in the new year.

Cheers

Brad

First in is the plinth on adjustable feet for levelling.

The carcasses are simply boxes of veneered MDF

The end panels with wrap-round face frames are then attached

The cornice is ready made in the workshop and slid into position

The doors are fitted with concealed hinges and we're finished

The customer was delighted and and confirmed that they want us to build them a new bling kitchen in the new year.

Cheers

Brad