- Joined

- 6 Jun 2011

- Messages

- 2,905

- Reaction score

- 808

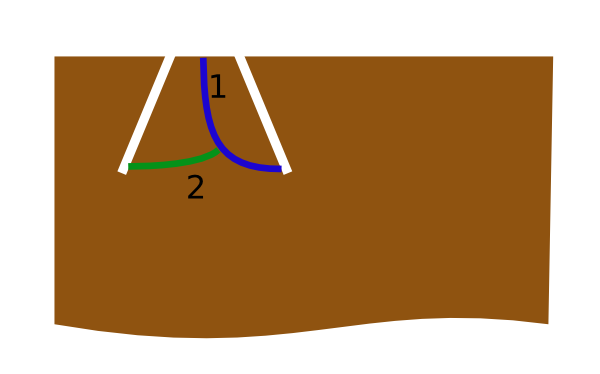

bugbear":3pw4j24o said:Peter Sefton":3pw4j24o said:The teeth should cut on the back stroke as a Japanese saw to keep the blade in tension.

Not true if (and only if, mark you) the frame is stiff enough. A stiff frame puts enough tension

on that you can quite happily cut on the push stroke, without the blade going slack (with

all the trouble that causes).

BugBear

BB i am surprised you say that, Here is a video of setting up a saw blade. Not that I am saying you need to buy one as expensive as this.

https://www.youtube.com/watch?v=cMJtK93agQ0

Peter