Silas Gull

Established Member

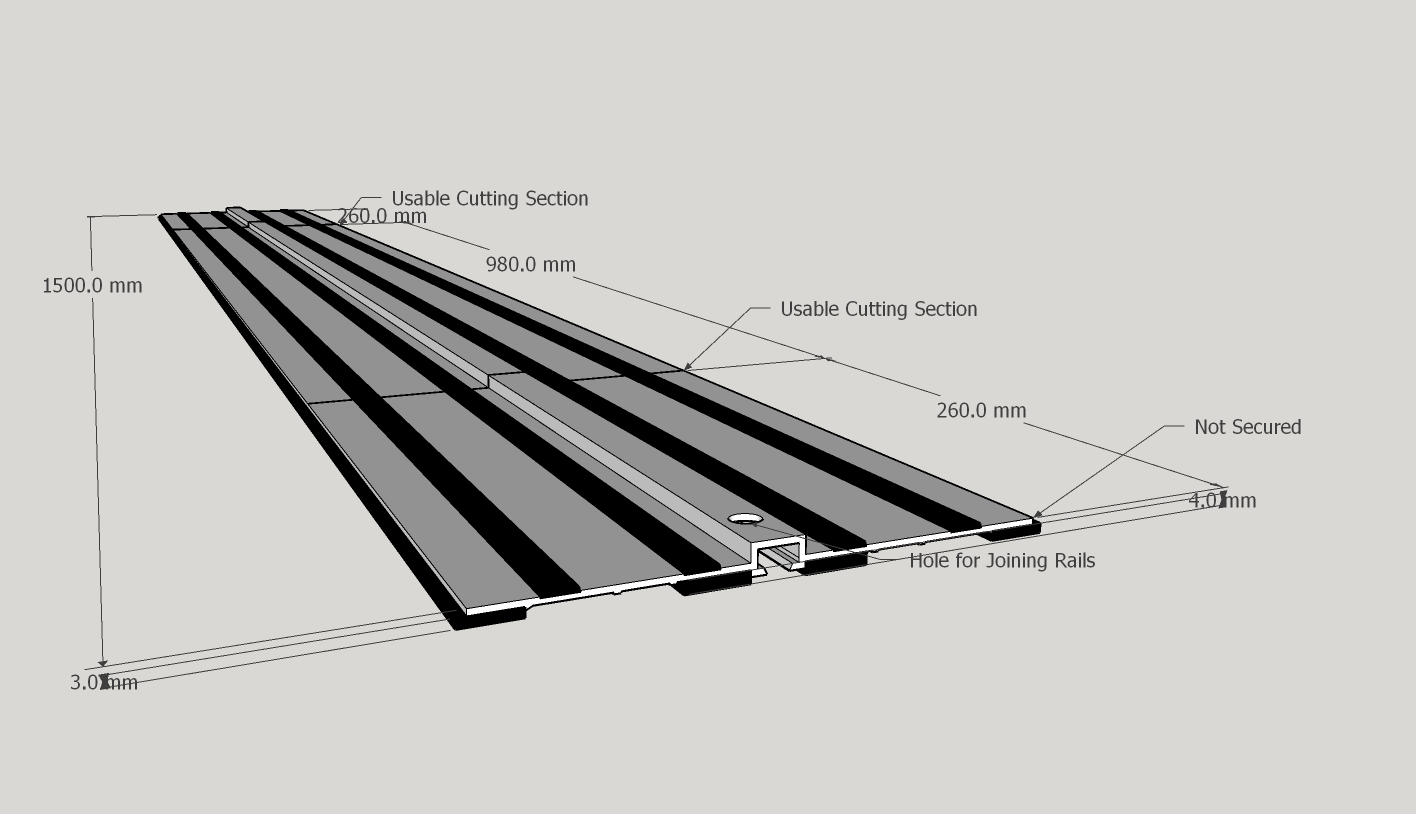

For sometime now I had been noticing that the black splinter-strips on our workshop saw tracks have been getting thinner and thinner. A more detailed examination revealed that there was a lot of play when the saw was mounted on the rail, but relocking the widgets that cancel the play only pulled the blade even closer to the splinter strip. In fact it is now only clearing the aluminium guide by half a mill. What would the point be, I was now wondering, of replacing the splinter strip? The blade would chew most of the visible portion off at the first pass!

An inspection of the channel on the saw' s baseplate shows two critically worn surfaces, one fore, one aft, which would ordinarily allow the base plate to be be set so as to allow a good 1.5 mm of visible splinterstrip to remain between the inside surface of the blade and the guide. It seems extraordinary that these aluminium surfaces have worn down faster than the opposing plastic eccentric cams, but they plainly have, and if we carry on regardless, the blade will eventually chew up the edge of the guide rail.

The only solution is to replace the baseplate at a cost of 60 quid before renewing the splinter strips. Whilst this will solve the problem, there is the disappointment of knowing that a tool that is held in such high esteem has this detrimental flaw.

Do any other DWS 520 users experience a similar problem?

An inspection of the channel on the saw' s baseplate shows two critically worn surfaces, one fore, one aft, which would ordinarily allow the base plate to be be set so as to allow a good 1.5 mm of visible splinterstrip to remain between the inside surface of the blade and the guide. It seems extraordinary that these aluminium surfaces have worn down faster than the opposing plastic eccentric cams, but they plainly have, and if we carry on regardless, the blade will eventually chew up the edge of the guide rail.

The only solution is to replace the baseplate at a cost of 60 quid before renewing the splinter strips. Whilst this will solve the problem, there is the disappointment of knowing that a tool that is held in such high esteem has this detrimental flaw.

Do any other DWS 520 users experience a similar problem?