Deadeye

Established Member

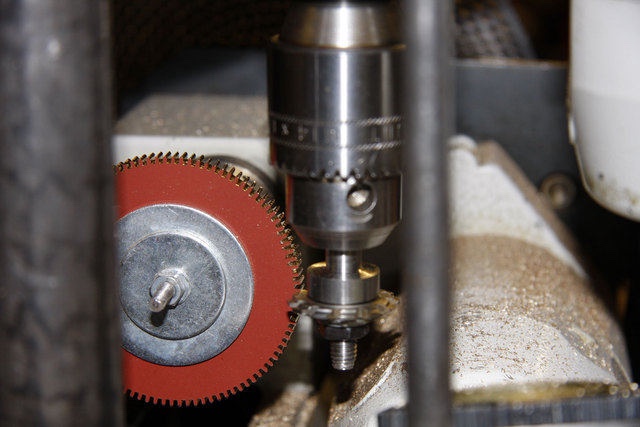

I've drawn up a (quite longstanding now) project that has lots of gears; 60-odd.

Originally I got them laser-cut in 3mm acrylic... but the laser cutting service produced a bevel rather than cutting vertically, which on the bore made them run off-true on the shaft and so miss-mesh (parallelograms in cross section not rectangles) even if the teeth might have tolerated the inaccuracy.

Because some of the gears run on nested tubes concentrically, the bores need to be different sizes.

Ideally I'd find a source of cheap nylon (or similar) modulus 1 or, better, modulus 2 gears, where I can drill my own bore from a, say, 1mm pilot (it's just a fun project, I don't want to throw a ton of cash at my prototype), and select gears from c.12 to c. 104 teeth. I need to stack them so flat is good. Modulus 0.5 I can find but are too small to accomodate the larger nested shafts. Any sources?

Failing that, I'd pay a bit more for metal ones and, failing *that*, I'd cut my own.... which brings me to second question: what's the best sheet material for this if my available tool is a scroll saw (I have a band saw but I think it won'y like to do even modulus 2 teeth)? Aluminium 2mm sheet? I have to both cut teeth and drill the bore. I also need to fix (CYA) some to the shafts (which are nested brass tubes). Brass sheet seems pretty expensive.

Advice very much welcomed.

Originally I got them laser-cut in 3mm acrylic... but the laser cutting service produced a bevel rather than cutting vertically, which on the bore made them run off-true on the shaft and so miss-mesh (parallelograms in cross section not rectangles) even if the teeth might have tolerated the inaccuracy.

Because some of the gears run on nested tubes concentrically, the bores need to be different sizes.

Ideally I'd find a source of cheap nylon (or similar) modulus 1 or, better, modulus 2 gears, where I can drill my own bore from a, say, 1mm pilot (it's just a fun project, I don't want to throw a ton of cash at my prototype), and select gears from c.12 to c. 104 teeth. I need to stack them so flat is good. Modulus 0.5 I can find but are too small to accomodate the larger nested shafts. Any sources?

Failing that, I'd pay a bit more for metal ones and, failing *that*, I'd cut my own.... which brings me to second question: what's the best sheet material for this if my available tool is a scroll saw (I have a band saw but I think it won'y like to do even modulus 2 teeth)? Aluminium 2mm sheet? I have to both cut teeth and drill the bore. I also need to fix (CYA) some to the shafts (which are nested brass tubes). Brass sheet seems pretty expensive.

Advice very much welcomed.