pren

Established Member

Hi.

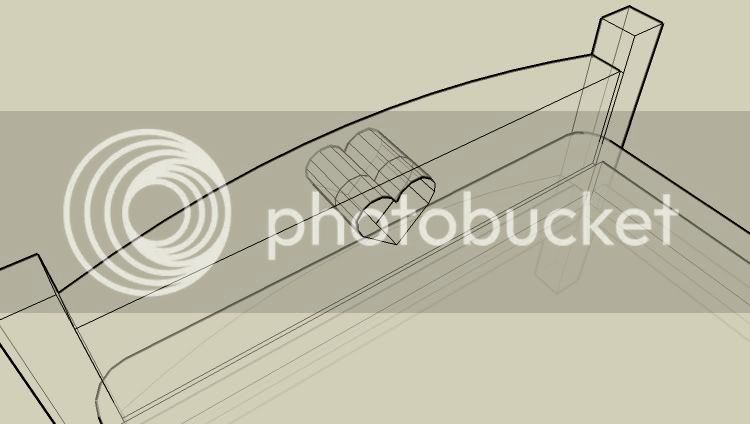

I'm designing a bed for a friend of mine. So far I've come up with the design below

One of the main features is the heart shape cut out of the head and foot boards. The head-board one is straight forward as it's flat. The issue is with the foot board. It's curved on one face and flat on the other.

I intend to join the edges of both cut-outs with some form of flexible timber, so they would both need to be exactly the same. The head and foot boards will be of a hollow, ribbed construction from 6 or 9mm MDF.

Any ideas how to cut the curved face so that it matches the flat one with out distorting around the curve? Or would it not be an issue? :?

I have a router at my disposal if that helps. I'll make a template to cut out the flat faces.

Trust me to make things difficult! :roll: :lol:

Thanks in advance.

Bryn

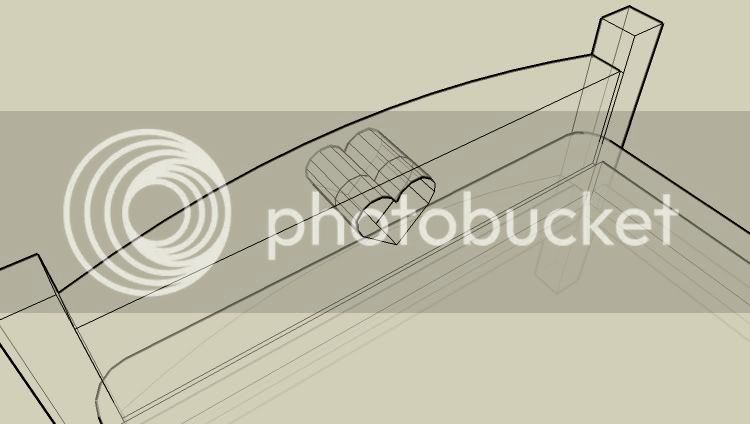

I'm designing a bed for a friend of mine. So far I've come up with the design below

One of the main features is the heart shape cut out of the head and foot boards. The head-board one is straight forward as it's flat. The issue is with the foot board. It's curved on one face and flat on the other.

I intend to join the edges of both cut-outs with some form of flexible timber, so they would both need to be exactly the same. The head and foot boards will be of a hollow, ribbed construction from 6 or 9mm MDF.

Any ideas how to cut the curved face so that it matches the flat one with out distorting around the curve? Or would it not be an issue? :?

I have a router at my disposal if that helps. I'll make a template to cut out the flat faces.

Trust me to make things difficult! :roll: :lol:

Thanks in advance.

Bryn