skipdiver":aw0ceihr said:

I need to do quite a few and quite regularly, so looking for something more efficient.

That is the killer statement.

I've been watching both your threads and find some of the advice given to be seriously 'suspect'. Yes, I'm sure you could do the odd 'one-off' of all of the items you've mentioned by the methods suggested but I'm equally sure that you would very soon be dis-satisfied with both the quality of the items you produce and the time it takes. There is also a serious issue of safety if you use milling cutters in pillar drills - they are not designed for 'lateral' forces and the chance of the chuck detaching itself from the quill is very high - I speak from experience!!

Similarly, using a router free-hand - even guided with a jig - is akin to an accident waiting to happen. Although Ali dose need relatively high speed for best finish (on my mill I work at about 12-1500), routers are far too fast, generally starting at about 3k.

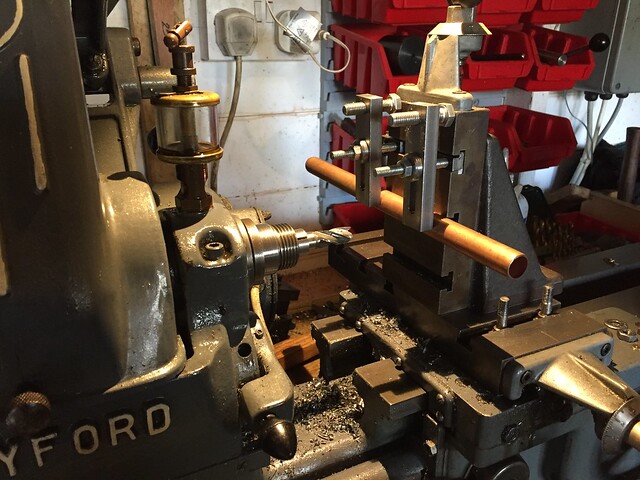

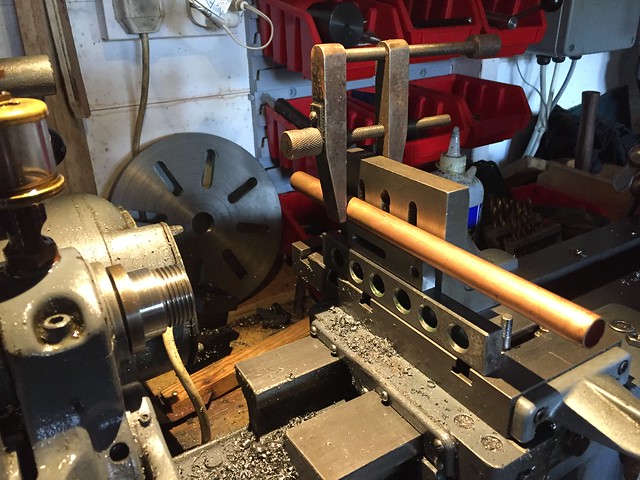

I still think that an investment in a small lathe is your best solution. No. it's not a milling machine but it is possible to do some milling operations on a lathe - just by thinking 'outside-the-box'. The work-piece doesn't

have to be in the chuck/collet, it can be mounted on the cross-slide - with a suitable jig (which you would have to make of course) - and the cutter can be held in the chuck/collet. I did a great deal of milling work like this on my Myford 7 before I bought the Warco Mill.

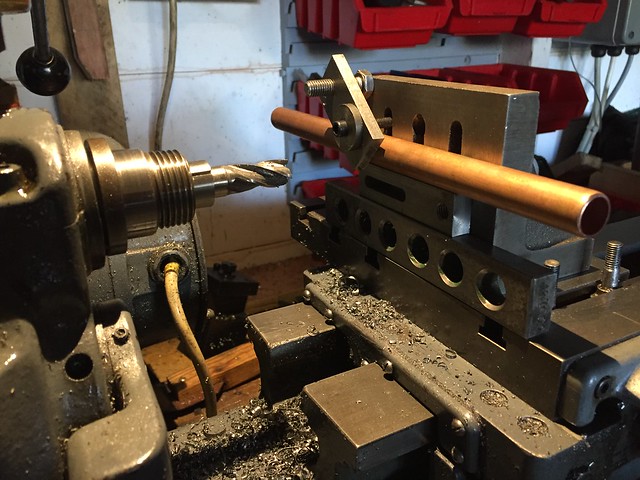

The slot in your ali tube is the particular project I'm thinking of here - though you haven't said how long the tube is so I am making certain assumptions that it is short enough to be accommodated in your workshop. The Warco web-site doesn't specify the travel for the cross-slide but since the Osaki is a smaller spec and has 65mm, I suspect that you could anticipate the 70mm you would need to cut a 75mm long slot 5mm wide. It would be better to have a margin of error of course and is a question to ask of Warco.

As far as Stainless Steel is concerned, as long as the environment for the component is not 'Marine' then either 303 or 304 would be easier to machine than 316 but whether running them on a grinder would surfice is down to what sort of 'finish' you want. In a lathe with a collet chuck, you could very easily 'dome' or just chamfer the end of a bar, part off, do the next until the batch needed is complete then re-mount each for a second operation on the other end, producing a quality product.