people do seem to get keen on these things so here's mine will upload in three sessions as there's a lot of pics

Frame first

Started with some botched legs i'd made (murdered) when I didn't have a clue - these came from the edge of a car park the bits used to stop people driving into the bushes Sapele or similar I think

please note previous shocking joinery and way way off centre holes - incredible how your stuff improves when you find this place

so cleaned those up by filling the holes and using a selection of power tools with a chisel at the end - much better

now for the cross bars - take some old oak fence posts - pictured with a selection of the tools used to get them ready (or prep my stock!) the half wood plane I got from a forum member a while ago with loads of other stuff for a fiver - he just wanted to see it used so here you are hope your looking!!

used it a bit like a scrub plane in case i hit a nail before it went in the planer/thicknesser

once cleaned up and sized cut the joints with a router

cleaned and fettled with chisel

it fits together!

i need to get these through to hold it

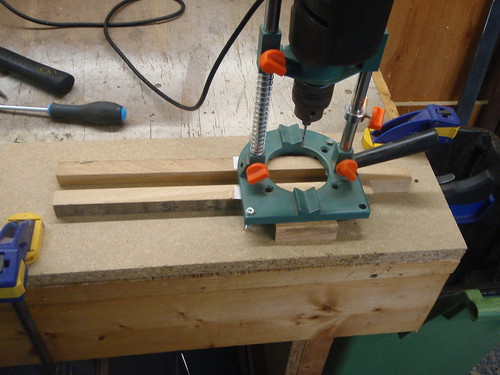

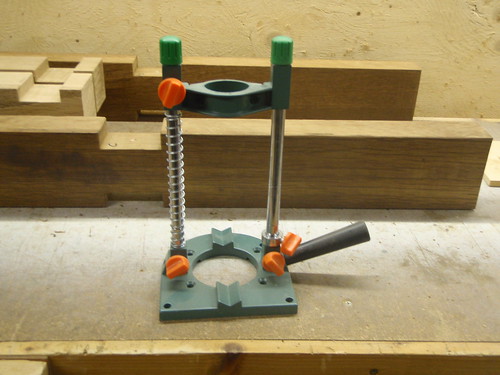

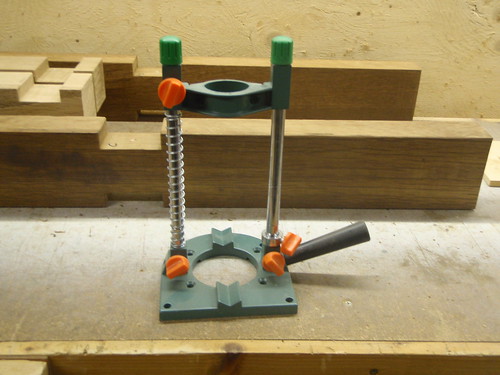

start with one of these (no drill press - on the list)

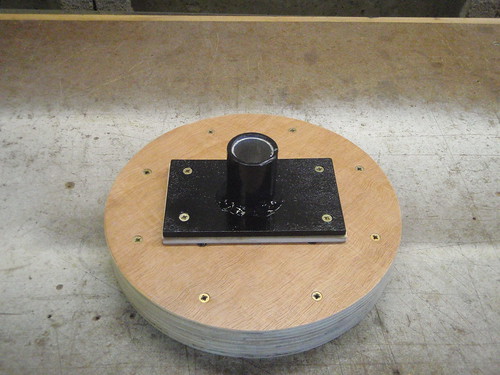

finish like this - not pretty but it works

chisel a rebate

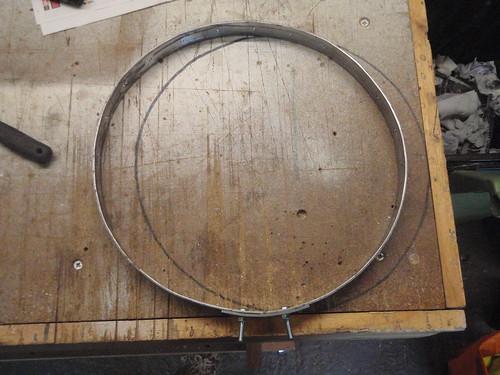

for this

coat of this or two

frame finished!

wingnuts used for reason revealed later - bolts m10 galvanised stainless would be better

and I must just say I love the contrast of these two woods together - i did a coffee table with oak and sapele (ithink) and they do go nice

anyway enough for one night will post the table section next - Cheers

Frame first

Started with some botched legs i'd made (murdered) when I didn't have a clue - these came from the edge of a car park the bits used to stop people driving into the bushes Sapele or similar I think

please note previous shocking joinery and way way off centre holes - incredible how your stuff improves when you find this place

so cleaned those up by filling the holes and using a selection of power tools with a chisel at the end - much better

now for the cross bars - take some old oak fence posts - pictured with a selection of the tools used to get them ready (or prep my stock!) the half wood plane I got from a forum member a while ago with loads of other stuff for a fiver - he just wanted to see it used so here you are hope your looking!!

used it a bit like a scrub plane in case i hit a nail before it went in the planer/thicknesser

once cleaned up and sized cut the joints with a router

cleaned and fettled with chisel

it fits together!

i need to get these through to hold it

start with one of these (no drill press - on the list)

finish like this - not pretty but it works

chisel a rebate

for this

coat of this or two

frame finished!

wingnuts used for reason revealed later - bolts m10 galvanised stainless would be better

and I must just say I love the contrast of these two woods together - i did a coffee table with oak and sapele (ithink) and they do go nice

anyway enough for one night will post the table section next - Cheers