Morning all,

Here's a quick WIP from me. My camera tripod only came with one quick-release shoe, which SWMBO keeps pinching! :evil: So I thought I'd knock up a second one.

Of course, halfway through this project I discovered you can buy new shoes quite cheaply But I'm committed now!

But I'm committed now!

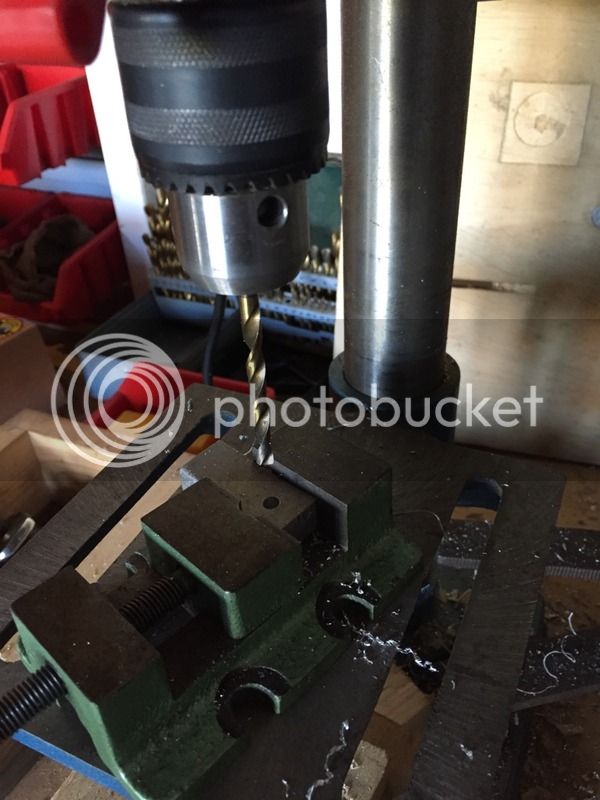

I don't have a milling machine, so here I'm milling the first edge flat with a flycutter. The aluminium I'm using is a random offcut that I inherited with the lathe:

Once the datum edges were milled, I marked out the rest with a scribing block on the surface plate. Then I hacksawed the block to the rough size and finished the remaining edges on the lathe:

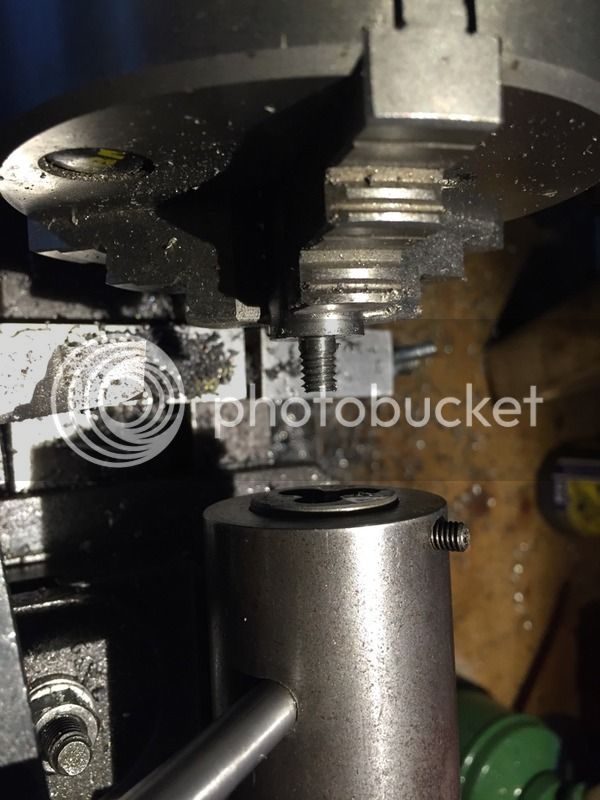

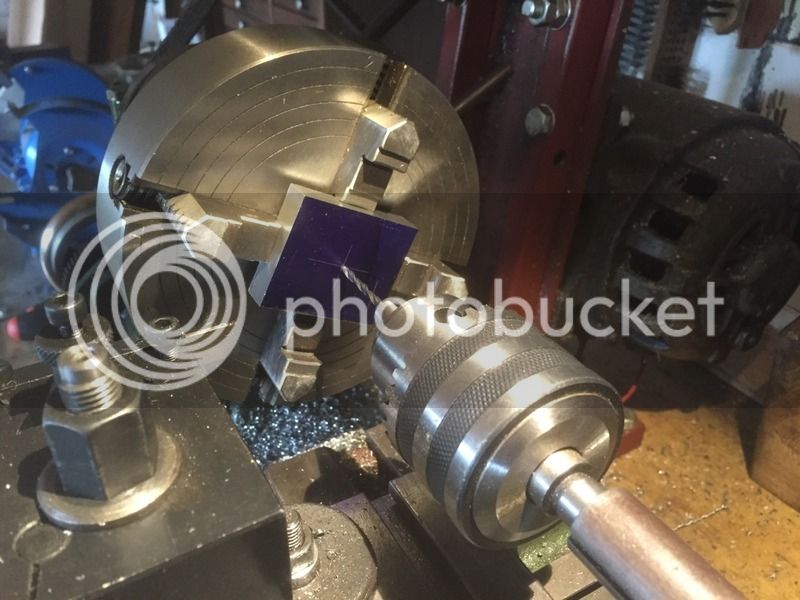

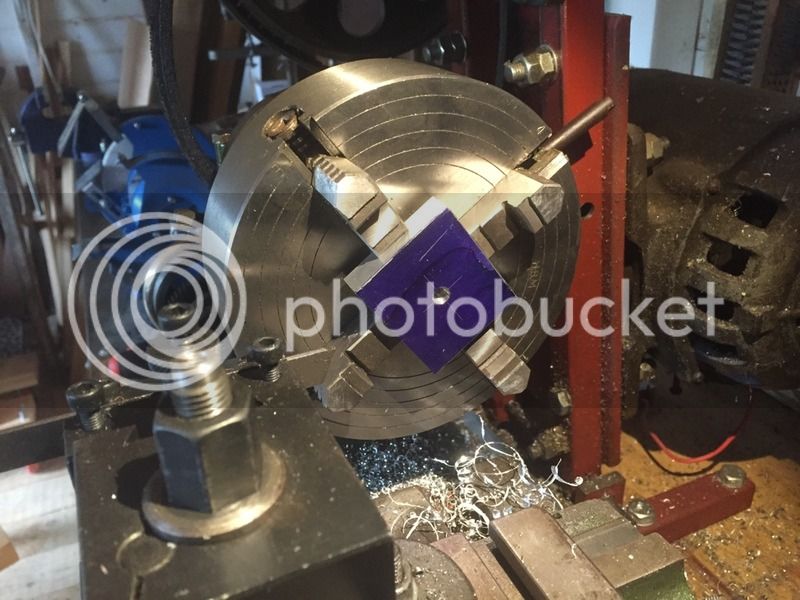

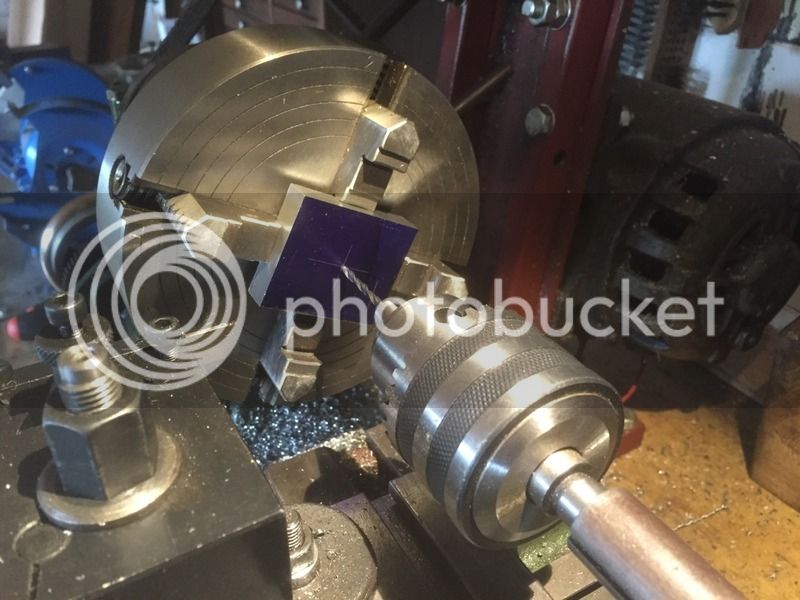

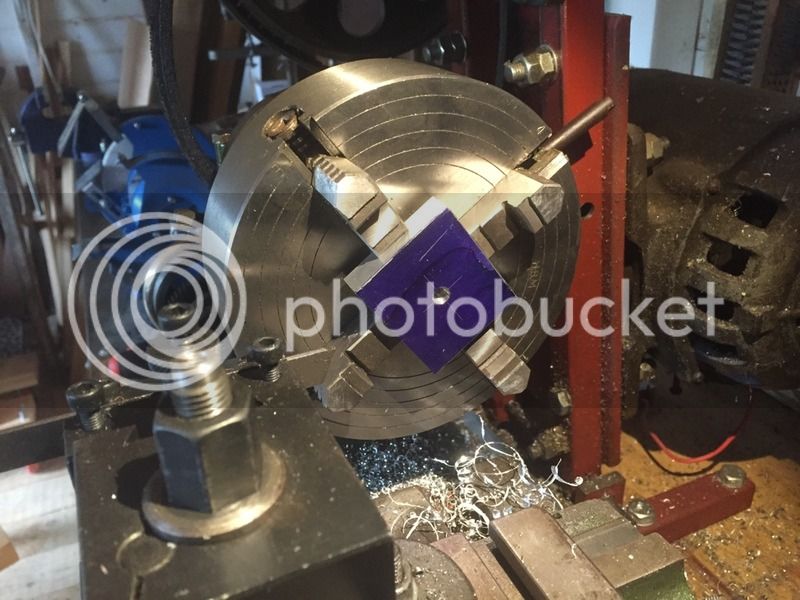

Next I mounted it in the four jaw chuck to drill the centre hole:

Then counterbored the hole to take the screw:

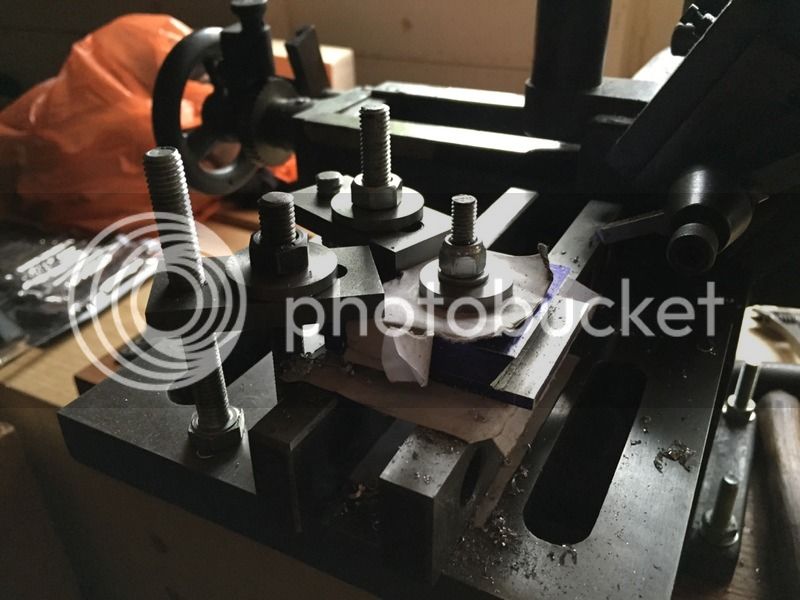

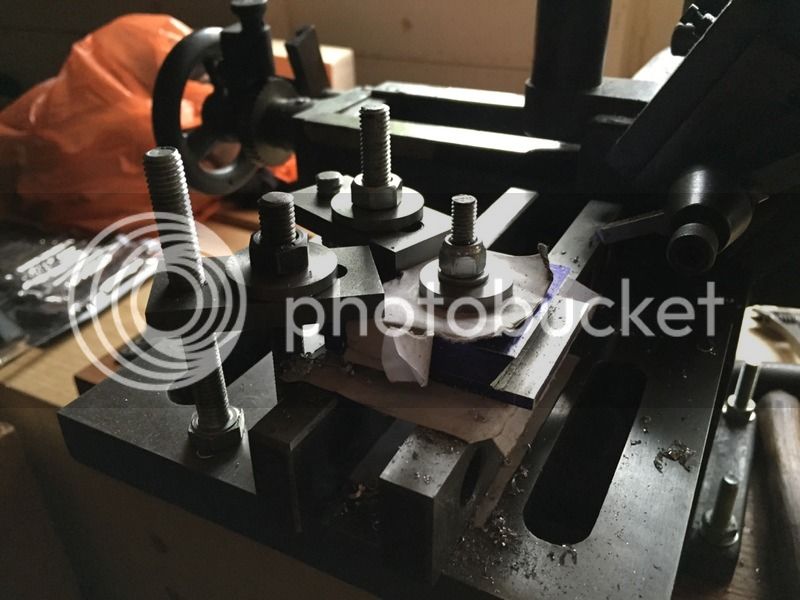

Now to shape the dovetails. I doing this on my Cowells hand shaper:

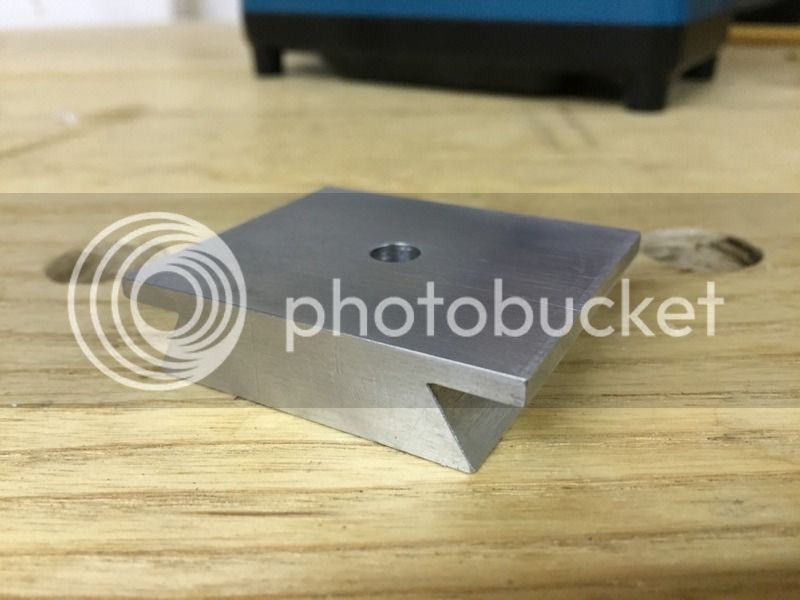

One dovetail done:

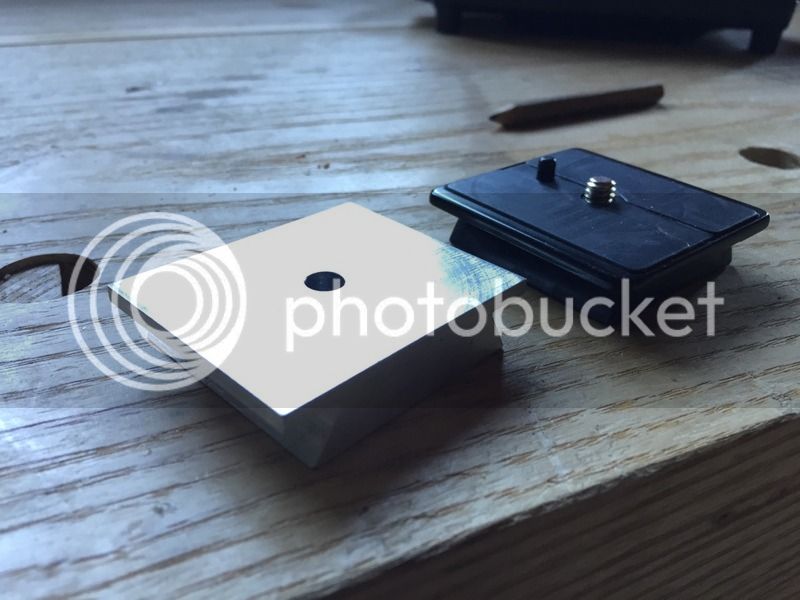

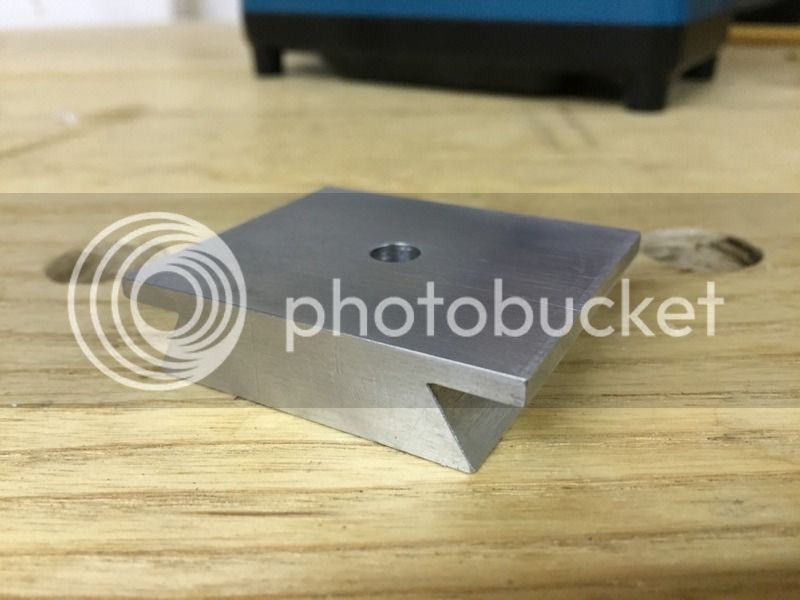

And the finished block:

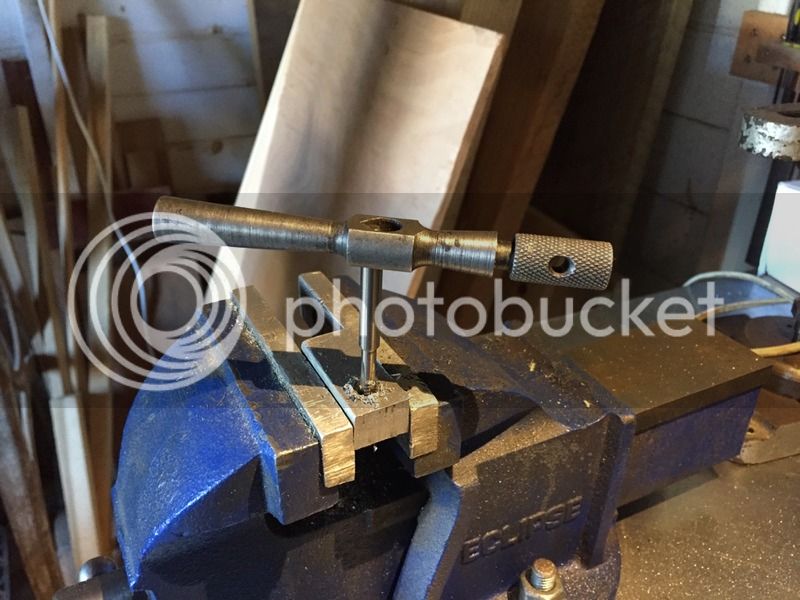

Today's job is to make the screw!

Here's a quick WIP from me. My camera tripod only came with one quick-release shoe, which SWMBO keeps pinching! :evil: So I thought I'd knock up a second one.

Of course, halfway through this project I discovered you can buy new shoes quite cheaply

I don't have a milling machine, so here I'm milling the first edge flat with a flycutter. The aluminium I'm using is a random offcut that I inherited with the lathe:

Once the datum edges were milled, I marked out the rest with a scribing block on the surface plate. Then I hacksawed the block to the rough size and finished the remaining edges on the lathe:

Next I mounted it in the four jaw chuck to drill the centre hole:

Then counterbored the hole to take the screw:

Now to shape the dovetails. I doing this on my Cowells hand shaper:

One dovetail done:

And the finished block:

Today's job is to make the screw!