John Smith

Established Member

I didn't get to spend as much time in the workshop as I had hoped today but did start to machine the pieces for the first four sash boxes.

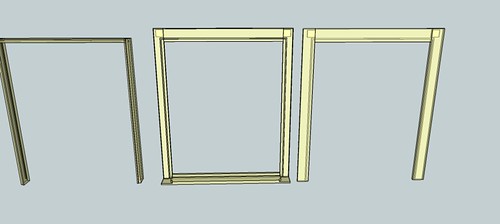

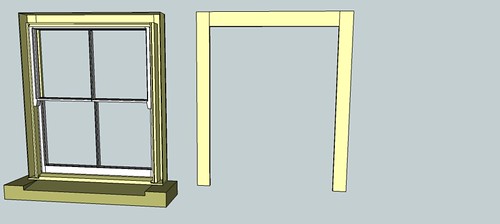

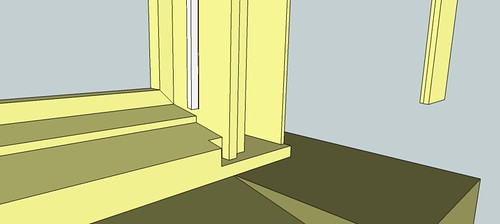

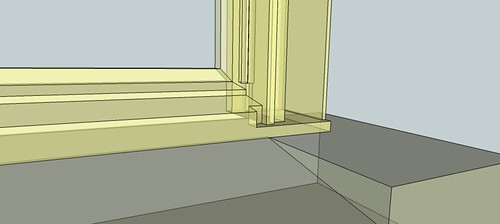

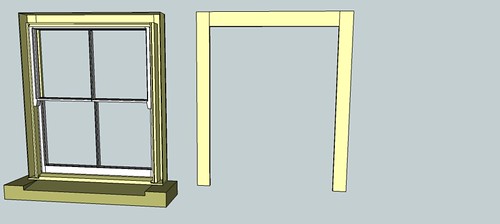

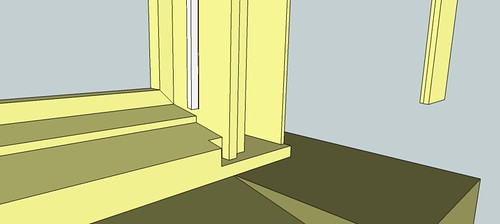

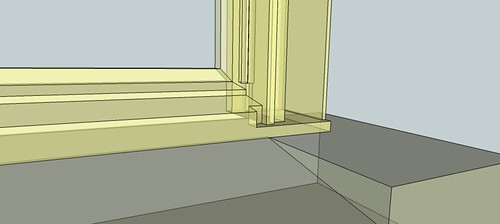

I have started to play with sketch up recently although the detail and final dimensions are not correct yet here are some sketches of the type of window Im building first.

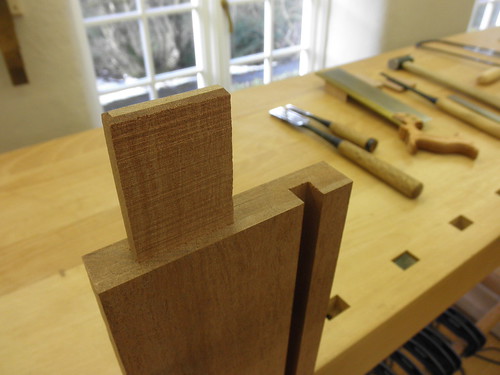

I have done some research on sash windows seals and am planning to use a two part parting bead

The u section fits into a routed grove in the pulley stile

and the parting bead snaps into that

This seems like a good idea to me. Does anyone have any feedback?

I also plan to use some weather pile seals which will be fitted into a routed grove in the staff bead and meeting rails

John

I have started to play with sketch up recently although the detail and final dimensions are not correct yet here are some sketches of the type of window Im building first.

I have done some research on sash windows seals and am planning to use a two part parting bead

The u section fits into a routed grove in the pulley stile

and the parting bead snaps into that

This seems like a good idea to me. Does anyone have any feedback?

I also plan to use some weather pile seals which will be fitted into a routed grove in the staff bead and meeting rails

John