wallace

Established Member

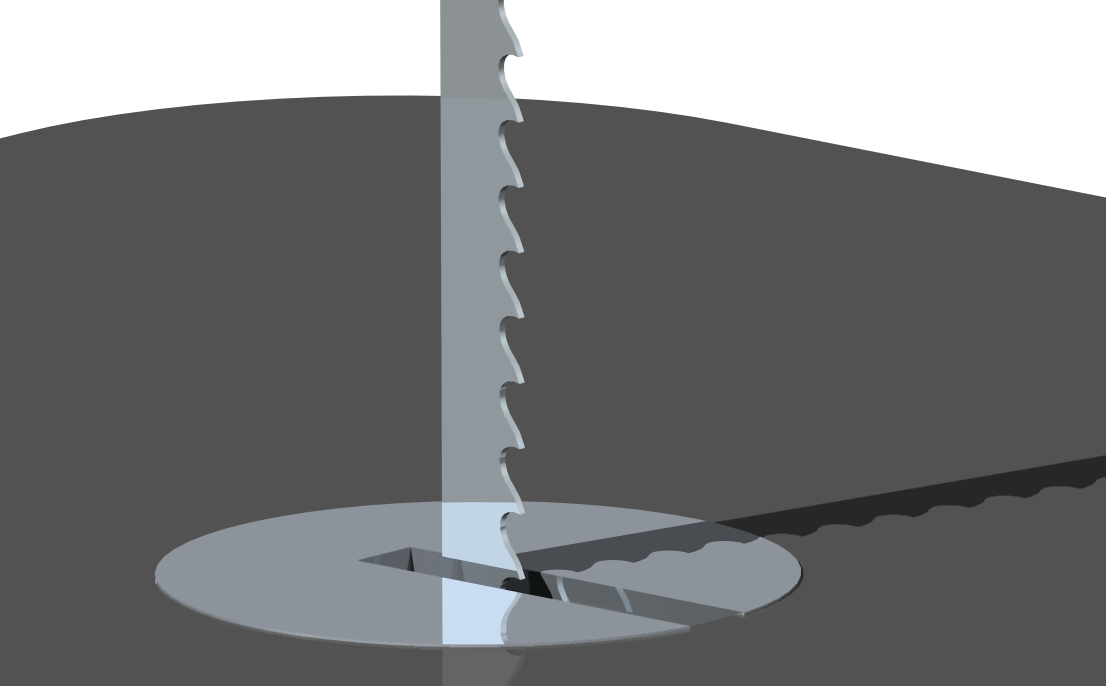

Hi all I have a wadkin DR 30" which is 5hp ran from a static converter. I am trying to rip some 9" thick Victorian pine joists into floor boards for my workshop. I have a new sabre cut 3tpi from tuffsaws. My saw is struggling and progress is not as quick as I thought it would be. If I push remotely quickish my saw bogs down and starts to stall. The static is at its max and if I push too hard the boost comes on and you can tell its struggling. I know I'm not getting the full hp of the saw because of the static, I have a biggish motor idling to help balance the 3 phase supply better. The moisture content of the wood around 25%. Any ideas? I have contacted Ian to ask him his thoughts.