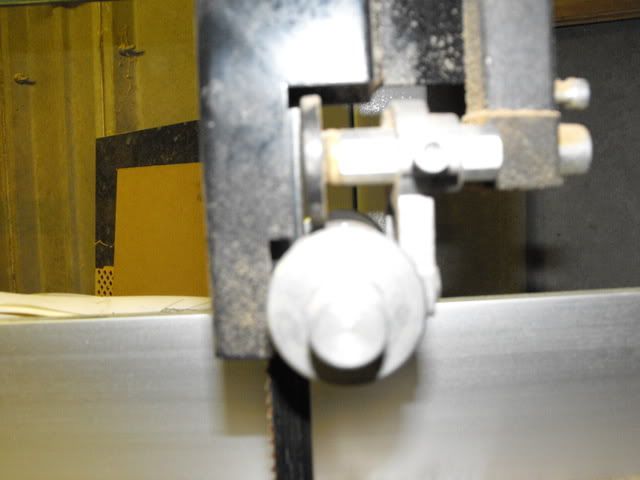

hello, im having problems cutting straight line on my bandsaw, when free handing, and also when using rip fence. its bugging me, coz im not using machine to its full potneial.

also i can seem to push the blade in quite a bit, even wen temtions is wound up.

any idea what it could be.

also i can seem to push the blade in quite a bit, even wen temtions is wound up.

any idea what it could be.