sealover1

Established Member

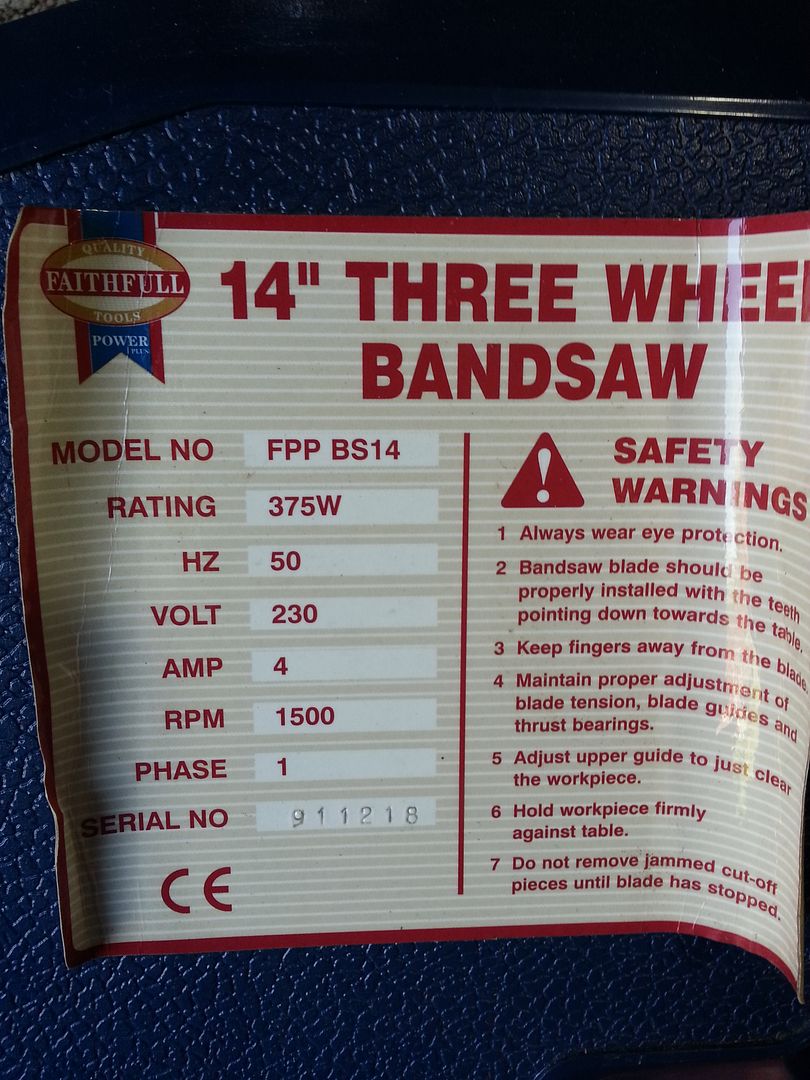

hi I just got a faithfull 14" bandsaw but the blade keeps coming off though if I cut really really slowly sometimes it will stay on for longer either way its a pain.

do you think its the blade being quite old causing this as it don't seem to be on there that tight to me and the tension is as far as it will go. and I cant seem to find a blade for that name can anyone help with that please? does it have to be for that make or can any blade the same length fit not even sure of the length.

cheers

do you think its the blade being quite old causing this as it don't seem to be on there that tight to me and the tension is as far as it will go. and I cant seem to find a blade for that name can anyone help with that please? does it have to be for that make or can any blade the same length fit not even sure of the length.

cheers