mailee

Established Member

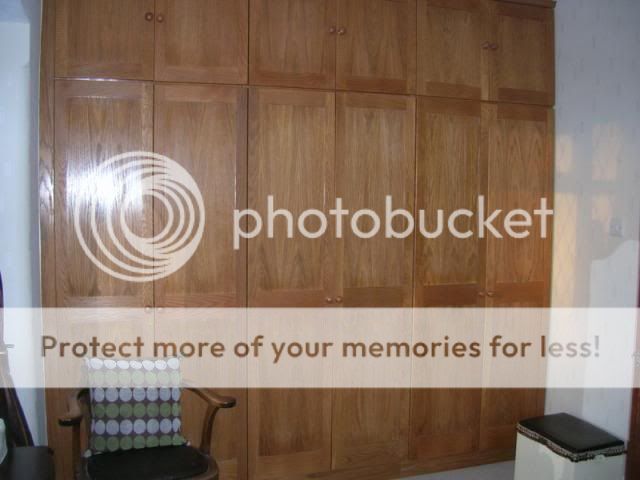

Yesterday I started work on another set of wardrobes. Again they are in oak veneered MDF. This one is a little different as one of the 'robes' houses the immersion heater and associated pipework, for this reason one of them will have to be built on site as a framework rather than the usual 'boxes'.

With a short break to fit the small gate this morning I managed to get the large panels cut out along with the tops and bottoms. I then cut the biscuit slots in them all and lipped the edges with oak.

I also made up the plinth for these two and another section of plinth which will be removable in case the immersion tank needs replacing. (these are in glue up so no pics at the moment) I shall make the third robe as a face frame to match in with the others and use battens for the shelving. Inside I shall make a slatted section to hide the tank and have two slatted shelves above it. There are a lot of pipes in there so I figured this would be the best way of building it.

With a short break to fit the small gate this morning I managed to get the large panels cut out along with the tops and bottoms. I then cut the biscuit slots in them all and lipped the edges with oak.

I also made up the plinth for these two and another section of plinth which will be removable in case the immersion tank needs replacing. (these are in glue up so no pics at the moment) I shall make the third robe as a face frame to match in with the others and use battens for the shelving. Inside I shall make a slatted section to hide the tank and have two slatted shelves above it. There are a lot of pipes in there so I figured this would be the best way of building it.